Ho etsa lieta mochini oa laminating

Thepa ea ho etsa lieta haholo-holo e entsoe ka likarolo tse hlano tse latelang

1.Letlalo.

Letlalo lea tenyetseha empa le tšoarella, le tiile joalo ka ha le le boreleli.E rekere, kahoo e ka otlolloa empa e hanela ho taboha le ho khojoa.

2.Masela.

Lesela le boetse le sebelisoa haholo ho etsa lieta.Joalo ka letlalo, masela a fumaneha ka mefuta e mengata e fapaneng ea mebala le mefuta.

3.Synthetics.

Lisebelisoa tsa maiketsetso li tsamaea ka mabitso a mangata a fapaneng- letlalo la PU kapa PU feela, letlalo la maiketsetso kapa li-synthetics feela- empa kaofela li tšoana ka ho ba metsoako e 'meli e entsoeng ke motho.

4.Rabara.

Rubber e atisa ho sebelisoa lieta ho etsa li-soles.

5. Lefuba.

Foam ke thepa e tloaelehileng ka ho fetisisa e sebelisetsoang ho fana ka tšehetso ka holimo ho lieta tsa mefuta eohle, ebang ke letlalo, masela, maiketsetso kapa esita le rabara.

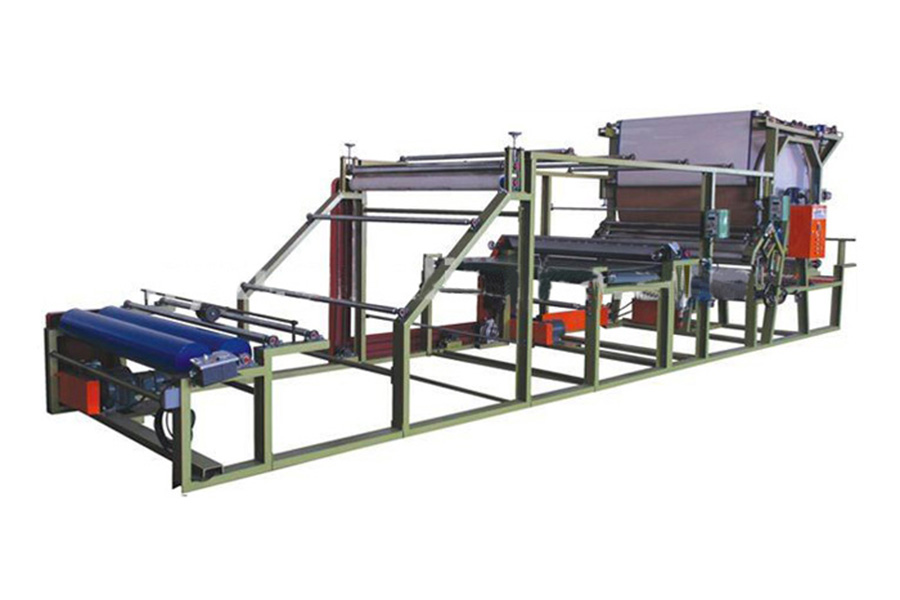

Likarolo tsa Mochini oa Laminating

1.E sebelisa sekhomaretsi sa metsi.

2.Ntlafatsa boleng ba lihlahisoa haholo, boloka litšenyehelo.

3. Sebopeho se otlolohileng kapa se otlolohileng, sekhahla se tlase sa ho senyeha le nako e telele ea tšebeletso.

4. Rolara ea ho fepa lintho tse bonahalang e khannoa ke cylinder ea moea, e lemoha mokhoa o potlakileng, o loketseng le o nepahetseng haholoanyane.

5. A hlomelloa ka boleng bo phahameng mocheso ho hanyetsa letlooa lebanta ho etsa laminated thepa kopana haufi-ufi le omisa silindara, ho ntlafatsa ho omisa le ho tlama phello, le ho etsa laminated sehlahiswa bonolo, washable, le ho matlafatsa sekgomaretsi fastness.

6. Ho na le lehare la sekhomaretsi sa sekhomaretsi ho hohla sekhomaretsi ka ho lekana holim'a lesela mme moralo o ikhethang oa kanale oa sekhomaretsi o thusa ho hloekisa sekhomaretsi kamora ho lamination.

7. Mochine ona oa laminating o na le lihlopha tse peli tsa tsamaiso ea ho futhumatsa, mosebedisi a ka khetha mokhoa o le mong oa ho futhumatsa kapa lihlopha tse peli, ho fokotsa tšebeliso ea matla le litšenyehelo tse tlaase.

8. Sebaka sa ho futhumatsa se koahetsoeng ka Teflon e le hore se sebetse hantle ho thibela sekhomaretsi se chesang se qhibilihisang khahlanong le ho khomarela holim'a rolara le carbonization.

9. Bakeng sa li-clamp roller, phetoho ea lebili la letsoho ka bobeli le taolo ea pneumatic lia fumaneha.

10. Setsi sa taolo ea infrared centering ka tsela e atlehang se thibela ho kheloha ha lebanta la marang-rang le ho lelefatsa bophelo ba tšebeletso ea lebanta la marang-rang.

11. Liphaephe tsohle tse futhumatsang ka har'a rolara ea ho omisa li entsoe ka tšepe e sa hloekang 'me mocheso oa mochine o futhumatsang o ka ba holimo ho 160 celcius degree, esita le 200 celcius degree.Hangata ho na le lihlopha tse peli tsa tsamaiso ea mocheso ka har'a rolara ea ho omisa.Mocheso o tla fetoha ho tloha ho sete e le 'ngoe ho ea ho lihlopha tse peli.E bolokehile ebile e boloka matla.

12. Sesebelisoa sa ho bala le sesebelisoa sa ho khutlisetsa morao se kenngoa mochine.

Ho bonolo ho boloka mochine mme litšenyehelo tsa tlhokomelo li tlaase.

13. E na le yuniti ea taolo ea infrared centering e itekanetseng, e ka thibelang ho kheloha ha lebanta la marang-rang ka katleho, le ho netefatsa bophelo ba tšebeletso ea lebanta la marang-rang.

14. Ho etsoa ka mokhoa o ikhethileng hoa fumaneha.

15. Litšenyehelo tse tlaase tsa tlhokomelo le tse bonolo ho li boloka.

Mekhahlelo ea mantlha ea tekheniki

| Mokhoa oa ho futhumatsa | Mocheso oa motlakase / Ho futhumatsa oli / ho futhumatsa mouoane |

| Diameter (Rolara ea Mochini) | 1200/1500/1800/2000mm |

| Lebelo la ho Sebetsa | 5-45m/min |

| Matla a ho futhumatsa | 40kw |

| Palo ea li-volts | 380V/50HZ, 3 mohato |

| Tekanyo | 7300mm * 2450mm2650mm |

| Boima ba 'mele | 3800kg |

LBH

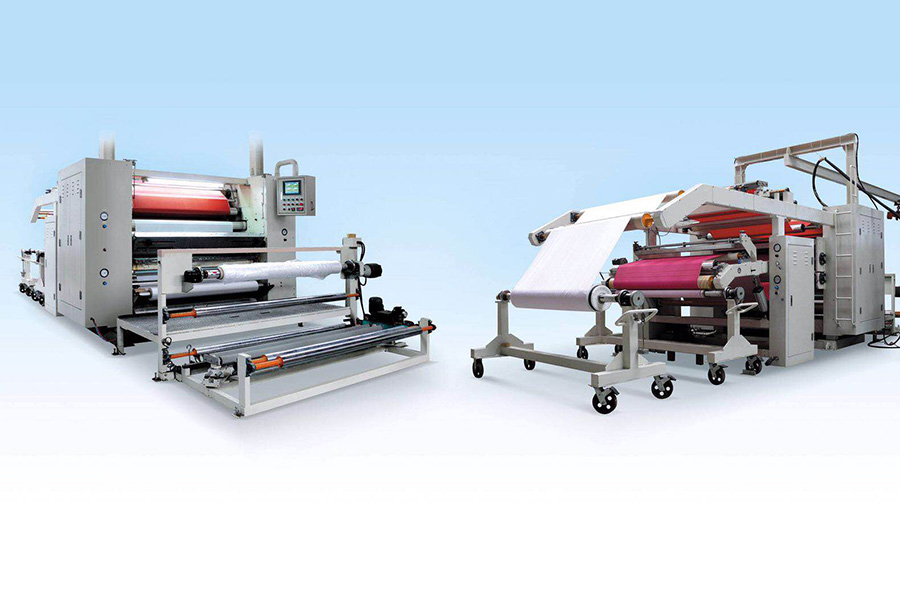

Mochini oa laminating ke eng?

Ka kakaretso, mochini oa laminating o bolela sesebelisoa sa lamination se sebelisoang haholo masela a lapeng, liaparo, thepa ea ka tlung, ka hare ho likoloi le liindasteri tse ling tse amanang le tsona.

E sebelisoa haholo bakeng sa ts'ebetso ea tlhahiso ea masela a mabeli kapa a mangata a masela a fapaneng, letlalo la tlhaho, letlalo la maiketsetso, filimi, pampiri, seponche, foam, PVC, EVA, filimi e tšesaane, joalo-joalo.

Haholo-holo, e arotsoe ka sekhomaretsi laminating le sa sekhomaretsi laminating, 'me sekgomaretsi laminating arotsoe ka metsi thehiloeng sekhomaretsi, PU oli sekgomaretsi, solvent-based sekhomaretsi, khatello ea kelello sekhomaretsi, super sekhomaretsi, chesang qhibiliha sekhomaretsi, joalo-joalo The non-sekgomaretsi mokhoa oa laminating boholo ba ka ho toba thermocompression bonding pakeng tsa thepa kapa lelakabe combustion lamination.

Mechini ea rona e etsa ts'ebetso ea Lamination feela.

Ke lisebelisoa life tse loketseng ho laminate?

1

(2) Lesela le nang le lifilimi, joalo ka filimi ea PU, filimi ea TPU, filimi ea PTFE, filimi ea BOPP, filimi ea OPP, filimi ea PE, filimi ea PVC ...

(3) Letlalo, letlalo la maiketsetso, Seponche, Foam, EVA, Plastiki....

Ke indasteri efe e hlokang ho sebelisa mochini oa laminating?

Mochini oa Laminating o sebelisoang haholo ho phethela masela, feshene, lieta, cap, mekotla le lisutuk'heise, liaparo, lieta le likatiba, mekotla, masela a lapeng, li-interiors tsa likoloi, mokhabiso, liphutheloana, li-abrasives, papatso, lisebelisoa tsa bongaka, lihlahisoa tsa bohloeki, thepa ea moaho, lintho tsa ho bapala. , masela a liindasteri, lisebelisoa tsa filthara tse se nang tikoloho joalo-joalo.

Joang ho khetha mochine o loketseng ka ho fetisisa oa laminating?

A. Ke lintlha life tse hlokahalang bakeng sa tharollo ea lintho tse bonahalang?

B. Ke litšobotsi life tsa thepa pele laminating?

C. Tšebeliso ea lihlahisoa tsa hau tsa laminated ke efe?

D. Ke lisebelisoa life tseo u lokelang ho li finyella ka mor'a lamination?

Nka kenya mochini le ho o sebelisa joang?

Re fana ka litaelo tse qaqileng tsa Senyesemane le livideo tsa ts'ebetso.Moenjiniere a ka boela a ea mose ho fektheri ea hau ho kenya mochine le ho koetlisa basebetsi ba hau hore ba sebetse.

Na ke tla bona mochini o sebetsa pele o reka?

Amohela metsoalle lefatšeng ka bophara ho etela feme ea rona nako efe kapa efe.