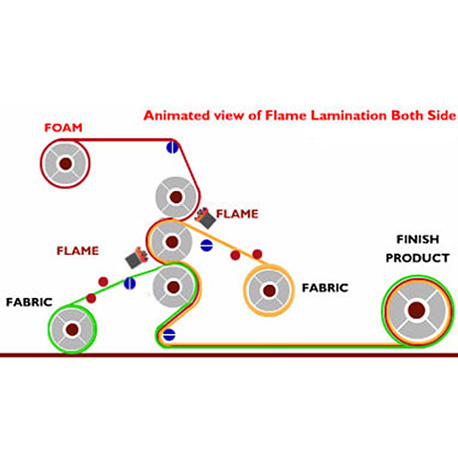

Mochini o kopantsoeng oa mollo oa seponche le masela

Lelakabemotsoakomochini o sebelisetsoa ho laminate foam ka lesela, le lohiloeng kapa le sa lohiloeng, le lohiloeng, masela a tlhaho kapa a maiketsetso, velvet, plush, boea ba polar, corduroy, letlalo, letlalo la maiketsetso, PVC, jj.

Flame Lamination Machine Features

1. E amohela PLC e tsoetseng pele, skrine ea ho ama le taolo ea motlakase oa servo, e nang le phello e ntle ea ho lumellana, ha ho na taolo ea ho fepa ka mokhoa o itekanetseng, ts'ebetso e phahameng e tsoelang pele ea tlhahiso, 'me tafole ea seponche e sebelisoa e le junifomo, e tsitsitseng ebile e sa lelefatsoe.

2. Lisebelisoa tse nang le likarolo tse tharo li ka kopanngoa ka nako e le 'ngoe ka ho chesa habeli ka nako e le' ngoe, e leng se loketseng tlhahiso ea bongata.Lihlopha tsa mollo tsa malapeng kapa tse tsoang linaheng tse ling li ka khethoa ho latela litlhoko tsa sehlahisoa.

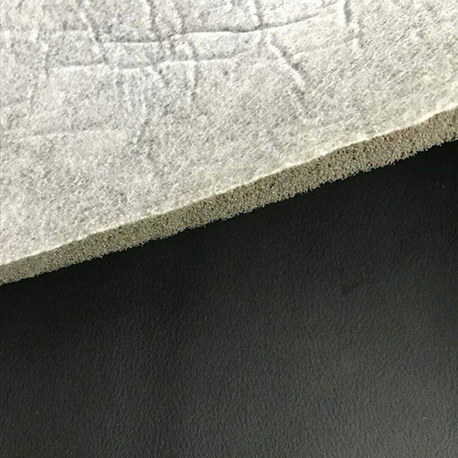

3. Sehlahisoa se kopantsoeng se na le melemo ea ts'ebetso e matla ea kakaretso, boikutlo bo botle ba matsoho, ho hanyetsa ho hlatsoa metsi le ho hloekisa ho omella.

4. Litlhoko tse khethehileng li ka etsoa ha ho hlokahala.

Thepa e Eketsehileng e Fumaneha

Lisete tse latelang tse ka kengoang hape mecheng e seng e ntse e le teng.

1.Guiding- le tentering diyuniti.

2.Accumulators bakeng sa foam, textile, backlining le thepa e phethiloeng.

3.Trimming diyuniti ho seam le arola sehlahiswa laminated.

4.Winding diyuniti: setsi sa matsoelintsoeke diyuniti, batch winding diyuniti, friction winding diyuniti bakeng sa unwinding & rewinding.

5.Likarolo tse tataisang bakeng sa masela a tsoelang pele le lihlopha tsa matsoeli.

6.Welding-mechine.

Litsamaiso tsa 7.Burner.

8.Mechini ea ho hlahloba.

9.Mechini e tsoelipanang

Mekhahlelo ea mantlha ea tekheniki

| Bophara ba Mocheso | 2.1m kapa e hlophisitsoeng |

| Mafura a tukang | Liquefied natural gas (LNG) |

| Laminating lebelo | 0~45m/mots |

| Mokhoa oa ho pholisa | tsidifatso ya metsi kapa ho phodisa moya |

E Sebelisoang Haholo Ka

Indasteri ea likoloi (ka hare le litulo)

Indasteri ea thepa ea ka tlung (litulo, sofa)

Indasteri ea lieta

Indasteri ea liaparo

Likatiba, liatlana, mekotla, lintho tsa ho bapala joalo-joalo

Litšobotsi

1. Mofuta oa Khase: Khase ea Tlhaho kapa Khase e Liquefied.

2. Sistimi ea ho futhumatsa metsi hantle e ntlafatsa phello ea lamination.

3. Diaphragm ea ho ntša moea e tla felisa monko.

4. Sesebelisoa sa ho jala masela se kenngoa ho etsa hore thepa ea laminated e be e boreleli le e makhethe.

5. Matla a tlamahano a itšetlehile ka thepa le foam kapa EVA e khethiloeng le maemo a ho sebetsa.

6. Ka botšepehi bo phahameng le nako e telele ea sekhomaretsi sa nako e telele, lisebelisoa tsa laminated li ama hantle 'me li omeletse ho hlatsoa.

7. Edge tracker, tensionless lesela sesebediswa unwinding, setempe sesebediswa le lisebelisoa tse ling tse thusang ka boikgethelo e kenngwa.