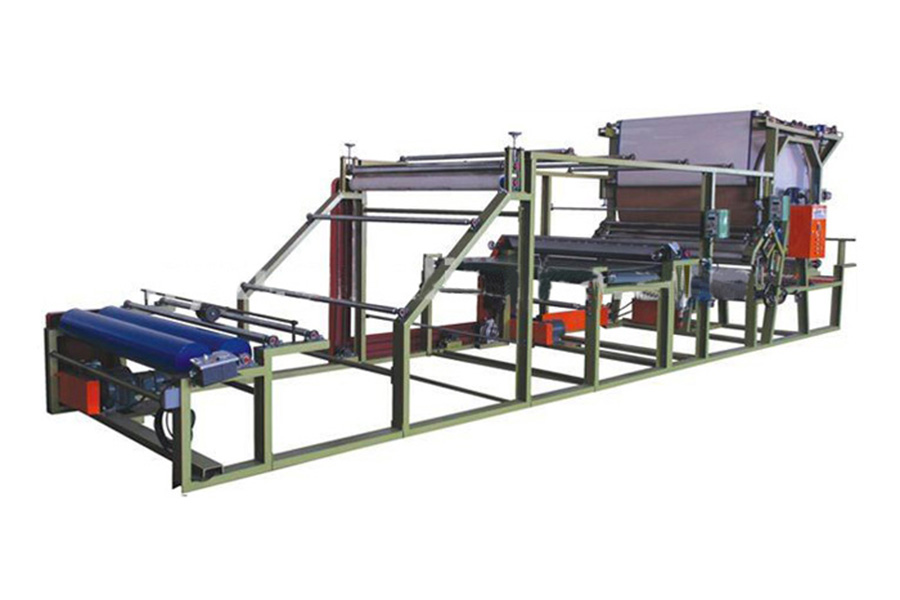

Takalma yin kayan laminating inji

Kayan yin takalma ya ƙunshi sassa biyar masu zuwa

1.Fata.

Fata tana da sassauƙa amma tana da ɗorewa, tana da ƙarfi kamar yadda take da ƙarfi.Yana da na roba, don haka ana iya miƙe shi duk da haka yana tsayayya da tsagewa da abrasion.

2.Textiles.

Fabric kuma ana amfani da shi sosai don yin takalma.Kamar fata, kayan yadi suna samuwa a cikin nau'ikan launuka da iri iri.

3.Synthetics.

Kayayyakin roba suna tafiya da sunaye daban-daban - fata PU ko kawai PU, fata na roba ko kuma kawai kayan aikin roba - amma duk iri ɗaya ne a cikin kasancewar ɗan adam na biyu.

4.Roba.

An fi amfani da roba a cikin takalma don yin tafin kafa.

5.Kumfa.

Kumfa shine mafi yawan kayan da ake amfani da su don samar da tallafi a cikin saman takalma na kowane nau'i, fata, yadi, roba ko ma roba.

Laminating Machine Features

1. Yana amfani da manne na tushen ruwa.

2.Inganta ingancin samfuran sosai, adana farashi.

3. Tsarin tsaye ko a kwance, ƙananan raguwa da kuma tsawon lokacin sabis.

4. Abin nadi na ciyar da kayan abinci yana motsa shi ta silinda iska, yana fahimtar mafi sauri, dacewa da daidaitaccen tsari.

5. Sanye take da high quality zafi juriya net bel don sa laminated kayan tuntube a hankali tare da bushewa Silinda, don inganta bushewa da bonding sakamako, da kuma sanya laminated samfurin taushi, washable, da kuma karfafa m fastness.

6. Akwai manne scraping ruwa don goge manne a ko'ina a kan masana'anta da kuma musamman manne tashar zane sauƙaƙe tsaftacewa na manne bayan lamination.

7. Wannan na'urar laminating tana da tsarin dumama nau'i biyu, mai amfani zai iya zaɓar yanayin dumama saiti ɗaya ko saiti biyu, don rage yawan kuzari da ƙarancin farashi.

8. Surface na dumama abin nadi ne mai rufi da Teflon domin efficacious hana zafi narke m da mai danko a saman nadi da carbonization.

9. Don abin nadi mai matsi, duka daidaitawar dabaran hannu da kuma sarrafa pneumatic suna samuwa.

10. atomatik infrared tsakiya kula naúrar yadda ya kamata ya hana net bel sabawa da tsawanta da net bel sabis lifespan.

11. Duk bututun dumama a cikin abin nadi na bushewa an yi su ne da bakin karfe kuma zazzabi na bushewar abin nadi zai iya kaiwa digiri 160 cecius, har ma da digiri 200.Yawancin tsarin dumama nau'i biyu ne a cikin abin nadi mai bushewa.Dumama zai canza ta atomatik daga saiti ɗaya zuwa saiti biyu.Yana da aminci da ceton kuzari.

12. An shigar da na'urar kirgawa da na'urar juyawa akan injin.

Yana da sauƙi don kula da injin kuma farashin kulawa yana da ƙasa.

13. Sanye take da atomatik infrared tsakiya iko naúrar, wanda zai iya yadda ya kamata hana net bel sabawa, da kuma tabbatar da net bel sabis rayuwa.

14. Musamman masana'antu yana samuwa.

15. Ƙananan farashin kulawa da sauƙi don kulawa.

Babban Ma'aunin Fasaha

| Hanyar dumama | dumama lantarki/ dumama mai/ dumama tururi |

| Diamita (Machine Roller) | 1200/1500/1800/2000mm |

| Gudun Aiki | 5-45m/min |

| Ƙarfin dumama | 40kw |

| Wutar lantarki | 380V/50HZ, 3 lokaci |

| Aunawa | 7300mm*2450mm2650mm |

| Nauyi | 3800kg |

FAQ

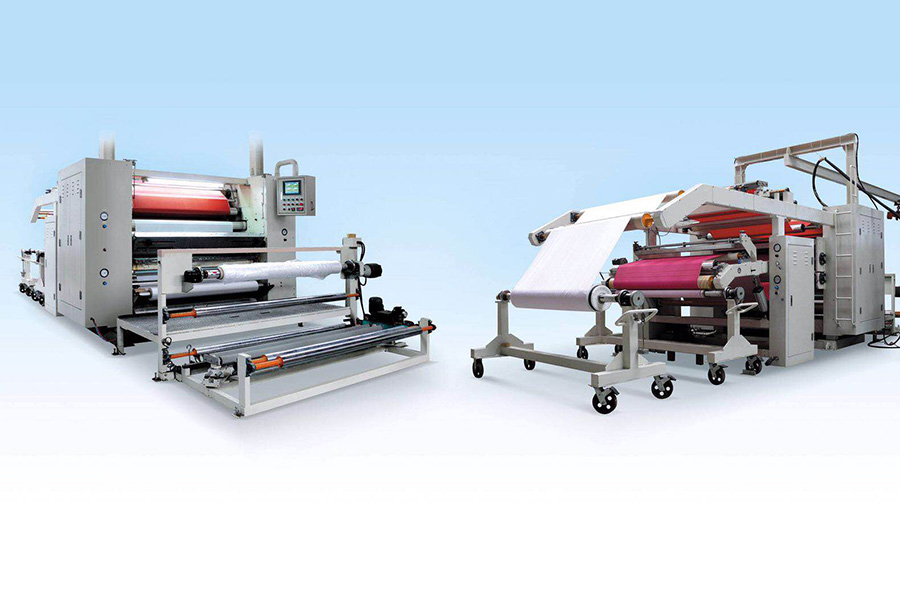

Menene injin laminating?

Gabaɗaya magana, na'urar laminating tana nufin na'urar da ake amfani da ita sosai a cikin kayan masaku na gida, tufa, kayan ɗaki, cikin mota da sauran masana'antu masu alaƙa.

An yafi amfani da biyu-Layer ko Multi-Layer bonding samar tsari na daban-daban yadudduka, na halitta fata, artifical fata, fim, takarda, soso, kumfa, PVC, EVA, bakin ciki fim, da dai sauransu.

Musamman, an kasu kashi m laminating da non-m laminating, da kuma m laminating ne zuwa kashi ruwa tushen manne, PU man m, sauran ƙarfi tushen manne, matsa lamba m manne, super manne, zafi narke manne, da dai sauransu The maras m. Tsarin laminating galibi shine haɗin haɗin kai tsaye na thermocompression tsakanin kayan ko lamination na ƙonewar wuta.

Injinan mu kawai suna aiwatar da Lamination.

Wadanne kayan da suka dace da laminating?

(1) Fabric da masana'anta: knitted yadudduka da saka, wadanda ba saka, mai zane, ulu, nailan, Oxford, Denim, karammiski, alatu, fata masana'anta, interlinings, polyester taffeta, da dai sauransu.

(2) Fabric da fina-finai, kamar PU fim, TPU fim, PTFE fim, BOPP fim, OPP fim, PE fim, PVC fim ...

(3) Fata, Fatar roba, Soso, Kumfa, EVA, Filastik....

Wace masana'antu ke buƙatar amfani da na'urar laminating?

Laminating inji yadu amfani da yadi karewa, fashion, takalma, hula, jakunkuna da akwatuna, tufafi, takalma da huluna, kaya, gida Textiles, mota ciki, kayan ado, marufi, abrasives, talla, likita kayayyaki, sanitary kayayyakin, gini kayan, toys. , masana'antu yadudduka, muhalli m tace kayan da dai sauransu.

Yadda za a zabi na'urar laminating mafi dacewa?

A. Menene dalla-dalla abin da ake bukata mafita?

B. Menene halaye na kayan kafin laminating?

C. Menene amfanin samfuran ku masu lanƙwasa?

D. Menene kaddarorin kayan da kuke buƙatar cimma bayan lamination?

Ta yaya zan iya girka da sarrafa injin?

Muna ba da cikakken koyarwar Ingilishi da bidiyoyin aiki.Injiniya kuma zai iya fita waje zuwa masana'antar ku don shigar da injin tare da horar da ma'aikatan ku don aiki.

Shin zan ga injin yana aiki kafin oda?

Barka da abokai a duk faɗin duniya don ziyartar masana'anta na kowane lokaci.