Mashiinka dhejinta kulaylka filimka dhejiska ah

Taxaddar Hawleed

1. Hawlwadeenku wuxuu ku shaqayn karaa qalabka kaliya ka dib markii uu si buuxda u yaqaan waxqabadka mashiinka iyo mabda'a shaqada.Qalabkan waa in uu ku shaqeeyaa qof gaar ah, kuwa aan shaqaynin waa in aysan furin oo aysan dhaqaaqin.

2. Kahor wax soo saarka, hubi in qalabka korontada sida fiilooyinka, wareegyada, xiriiriyeyaasha, iyo matoorada ay buuxiyeen shuruudaha.

3. Kahor wax soo saarka, hubi in sahayda korantada ee saddexda weji ay isku dheeli tiran tahay.Waa mamnuuc in qalabka lagu bilaabo wejiga luminta.

4. Inta lagu jiro xilliga wax-soo-saarka, waxaa lagama maarmaan ah in la hubiyo in kala-goysyada wareegga ahi ay badbaado yihiin, haddii dhuumaha aan xannibnayn, haddii ay jiraan waxyeello, daadinta saliidda, iyo baabi'inta waqtigeeda.

5. Kahor wax soo saarka, hubi in cadaadiska barometer kasta uu yahay mid caadi ah, haddii ay jirto hawo-baxa waddada gaaska, oo hagaaji waqtiga.

6. Hubi adkaynta kala-goysyada kasta ka hor inta aan la soo saarin, haddii ay jirto dabacsanaan ama daad, oo dib u hagaaji waqtiga.

7. Ka hor inta aan qalabka la soo saarin tiro yar, waa in marka hore la sameeyaa qadar yar oo tijaabo ah, ka dibna waa la soo saari karaa ka dib guusha.

8. Kahor wax soo saarka, xaaladaha sifaynta ee xarun kasta oo biyo-dhimis ah, yareeyaha, sanduuqa kabaha sida iyo furaha rasaasta waa in la hubiyaa.Saliidda Haydarooliga iyo saliidda saliidda waa in lagu daraa si sax ah iyo waqtigeeda.

9. Ka dib marka mishiinka la joojiyo, waxaa lagama maarmaan ah in la soo qaado qaybaha boodhka ururinaysa iyo qalabyada kale ee wakhtiga, oo ku dheji rullalaha caagga ah si aad uga saarto alaabta haraaga ah iyo wasakhda mashiinka isticmaalka soo socda.

10. Waa mamnuuc in dareeraha daxalka leh lagula xidhiidho rullaluistemadka caagga ah, lana hubiyo in dusha sare ee rullaluhu uu yahay mid nadiif ah oo aan lahayn wax shisheeye.

11. Waa mamnuuc in qashinka lagu ururiyo nidaamka martida loo yahay, lagana ilaaliyo nadaafadda agagaarkeeda oo aan lahayn wax shisheeye.Dammaanad qaaday saamayn laxaad leh kulayl gaar ah.

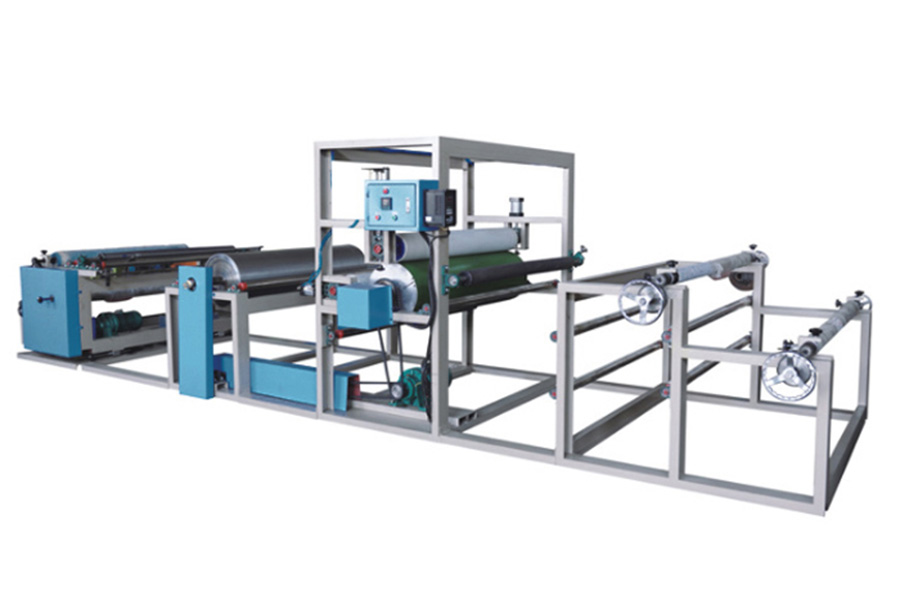

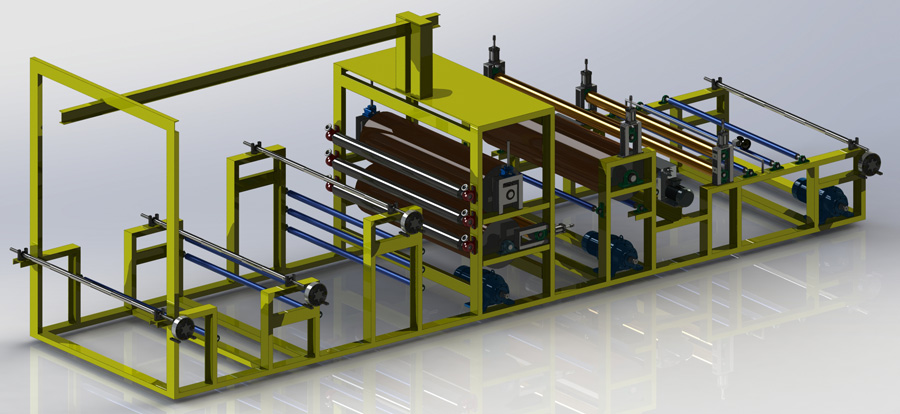

Halbeegyada Farsamo ee ugu muhiimsan

| Balaadhka alaabta | 1600mm |

| Ballaca rullaluistu | 1800mm |

| Xawaaraha | 0 ~ 35 m/daqiiqo |

| Cabbirka mashiinka (L*W*H) | 6600×2500×2500 mm |

| Awood | Qiyaastii 20KW |

| Matoorka | 380V 50Hz |

| Miisaanka mashiinka | 2000kg |

FAQ

Waa maxay mishiinka dahaadhida?

Guud ahaan, mishiinka wax lagu dhejiyo waxaa loola jeedaa qalabka wax lagu dhejiyo kaas oo si weyn loogu isticmaalo dharka guriga, dharka, alaabta guriga, gudaha baabuurta iyo warshadaha kale ee la xiriira.

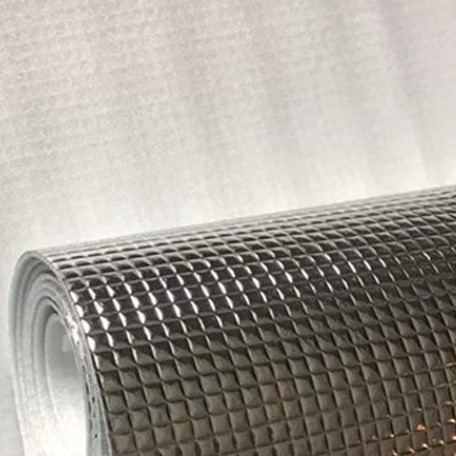

Waxaa inta badan loo isticmaalaa laba-lakab ama multi-lakab habka wax soo saarka bond bonding ee dhar kala duwan, maqaar dabiiciga ah, maqaar artifical, filim, warqad, isbuunyo, xumbo, PVC, EVA, filim khafiif ah, iwm.

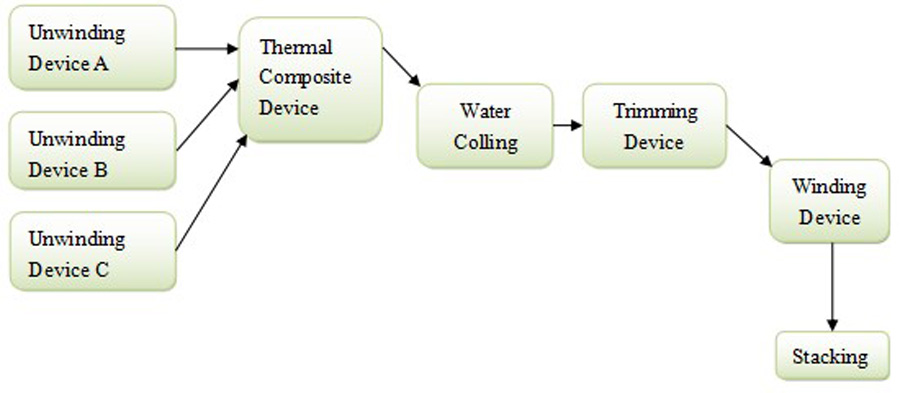

Gaar ahaan, waxa loo kala qaybiyaa xabagta xabagta iyo laminating non-dhesive, iyo laminating xabaggu waxa loo qaybiyaa koollada biyaha ku salaysan, xabagta saliidda PU, xabagta dareeraha ku salaysan, xabagta xasaasiga ah ee cadaadiska, xabagta super, xabagta kulul, iwm. Habka laminating inta badan waa isku xidhka kulaylka tooska ah ee ka dhexeeya alaabta ama daahyada ololka.

Mashiinadayadu waxay kaliya sameeyaan habka Lamination.

Qalabkee ku habboon laminating?

(1) Maro leh dhar: dhar tolan iyo tolmo, aan tolmo lahayn, funaanad, dhogorta, nylon, Oxford, Denim, Velvet, plush, dharka suede, interlinings, polyester taffeta, iwm.

(2) Maro leh filimaan, sida filimka PU, filimka TPU, filimka PTFE, filimka BOPP, filimka OPP, filimka PE, filimka PVC ...

(3) Harag, maqaar la sameeyay, isbuunyo, xumbo, EVA, caag....

Warshadee u baahan tahay iyadoo la isticmaalayo mashiinka dharka lagu dhejiyo?

Mashiinka laminating oo si ballaaran loogu isticmaalo dhameynta dharka, moodada, kabaha, koofiyadaha, bacaha iyo shandadadaha, dharka, kabaha iyo koofiyadaha, boorsooyinka, dharka guriga, gudaha baabuurta, qurxinta, baakadaha, abrasives, advertising, sahayda caafimaadka, alaabta nadaafadda, qalabka dhismaha, alaabta lagu ciyaaro , Dharka warshadaha, alaabta shaandhada deegaanka u fiican iwm.

Sidee loo doortaa mashiinka dharka lagu dhejiyo ee ugu habboon?

A. Waa maxay shuruudaha xalinta agabka tafatiran?

B. Waa maxay sifooyinka walxaha ka hor inta aan laminating?

C. Waa maxay isticmaalka alaabtaada dahaaran?

D. Waa maxay sifooyinka maadiga ah ee aad u baahan tahay si aad u gaadho ka dib markii la nadiifiyo?

Sideen u rakibi karaa ugana shaqayn karaa mishiinka?

Waxaan bixinaa tilmaamo Ingiriis ah oo faahfaahsan iyo fiidiyowyo hawlgal ah.Ingineerku waxa kale oo uu u bixi karaa dibadda si uu u rakibo mishiinka oo uu u tababaro shaqaalahaaga si ay u shaqeeyaan.

Miyaan arkaa mishiinka oo shaqaynaya ka hor intaan la dalban?

Ku soo dhawoow saaxiibada adduunka oo dhan si ay u soo booqdaan warshadeena wakhti kasta.