Mashiinka wax lagu dhejiyo ee dharka lagu dhejiyo

Faa'iidooyinka mashiinkayaga waa dusha duudduuban ee mashiinka laminating waxaa lagu farsameyn karaa laser si loo sameeyo qaabab kala duwan, taas oo hubin karta in lakabka koollada uu sii ahaado mid furan ama la joojinayo, ka fogaanshaha qulqulka koollada ee habka laminating, mabda'a rullaluistemadka waa oo la mid ah tikniyoolajiyadda daabacaadda, naqshadeynta qaab wanaagsan ee rullaluistemadka gravure ayaa ka dhigi kara daahan dharka iyo laminating si fiican.Tiknoolajiyada Xinlilong waxay bixisaa naqshado taxane ah oo roller-ka ah, kaas oo ka caawin kara macaamiisha inay go'aan ka gaaraan rullaluistemadka koowaad ama cusub ee mishiinka dahaarka, kaas oo hadda naga soo iibsaday.

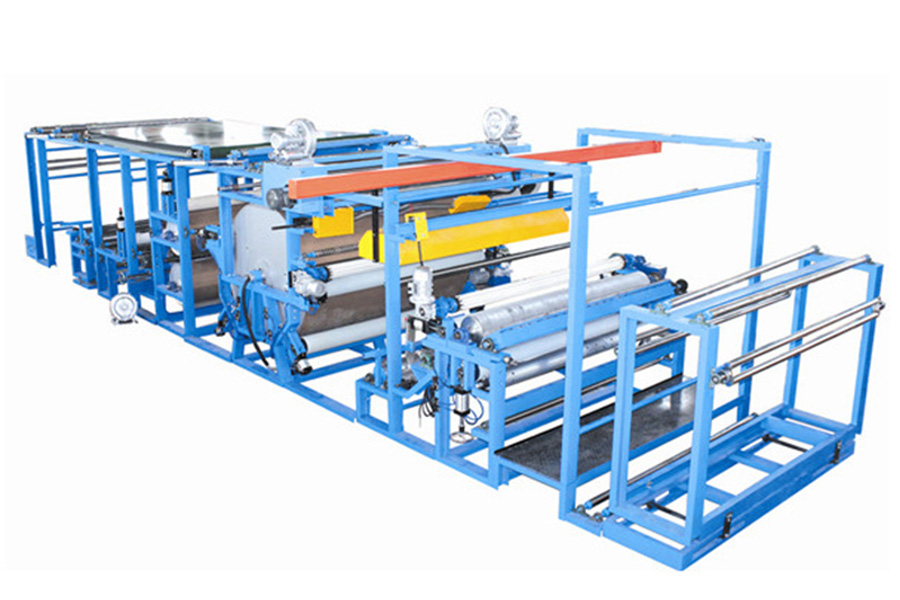

Qaab dhismeedka

Fabric to Fabric Laminating Machine

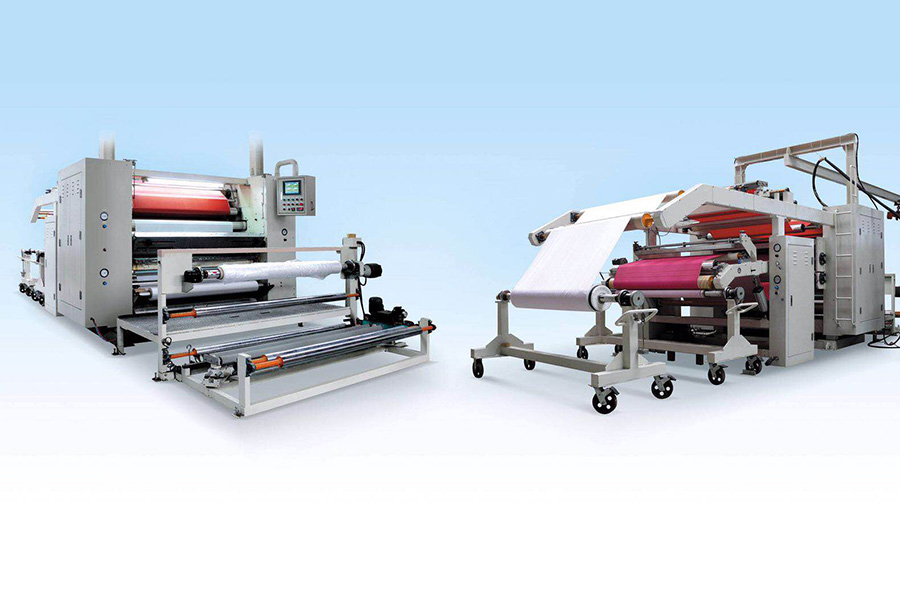

1. Codsaday in lagu dhejiyo oo lagu dhejiyo dharka, kuwa aan dunta lahayn, dunta, kuwa aan biyaha lahayn, filimada neefta iyo iwm.

2. Waxaa caawiyay xakamaynta barnaamijka PLC iyo interface taabasho-mashiinka, fududahay in la shaqeeyo.

3. Qalabka cidhifyada sare leh iyo qalabka wax lagu mariyo, mishiinkani wuxuu kordhiyaa heerka otomaatiga, wuxuu badbaadiyaa kharashka shaqada, wuxuu yareeyaa xoogga shaqada, wuxuuna kor u qaadaa waxtarka wax soo saarka.

4. Xabagta PU ama xabagta ku salaysan dareeraha, alaabta la dahaadhay waxay leeyihiin hanti koollo wanaagsan oo si fiican u taabta.Waa kuwo la dhaqi karo oo la nadiifin karo.Sababtoo ah xabagta ayaa ku jirta qaabka dhibcaha marka la daadinayo, alaabta la daboolay waa neefsasho.

5. Qalabka qaboojinta ee waxtarka leh ayaa kor u qaadaya saameynta lamination.

6. Tolida tolida waxaa loo isticmaalaa in lagu gooyo cidhifyada ceeriin ee alaabta la dahaadhay.

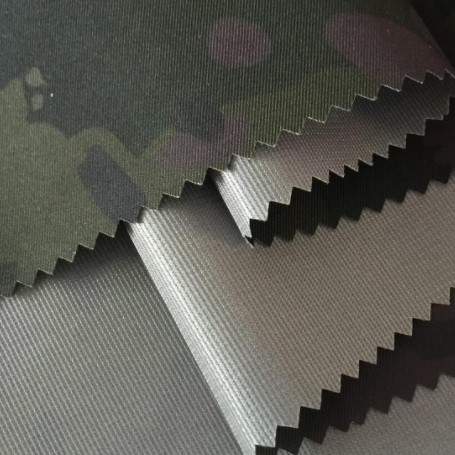

Walxaha dahaadhan

1.Fabric + dhar: dharka, maaliyada, dhogorta, nylon, Velvet, Terry maro, Suede, iwm.

2.Fabric + filimada, sida filimka PU, filimka TPU, filimka PE, filimka PVC, filimka PTFE, iwm.

3.Fabric+ Leather/Maqaar macmal ah, iwm.

4.Fabric + Nonwoven

5. Isbuunyo/ Xumbo leh Maro/ Maqaar macmal ah

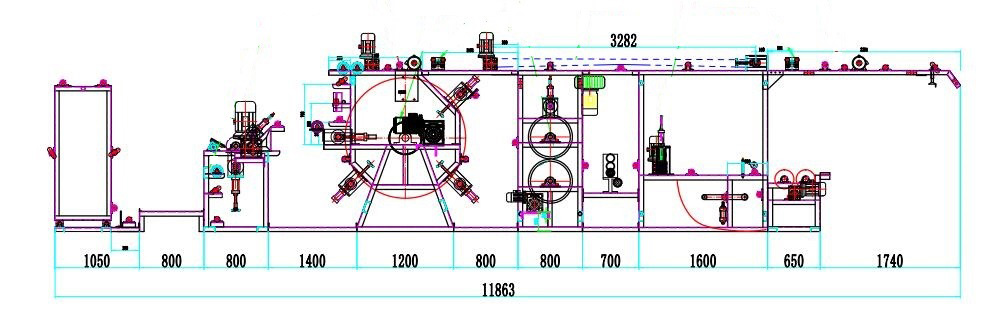

Halbeegyada Farsamo ee ugu muhiimsan

| Maya | Qaybaha ugu muhiimsan | FaahfaahinTilmaamids |

| 1 | Halbeegyada farsamada ugu weyn | 1) Ballaca Roller waa 1800mm, ewaxtar lehlaminaatballac ahaanwaa 1600mm. 2) Inta badan ee laminating dhar leh dhar,aan tolmo lahaynagabka,iyo walxo kale oo jilicsan iwm. 3) Habka xabagta: wareejinta xabagtaed by rullaluistemadka ku dheggan. 4) Habka kululaynta:Korontada. 5) Shaqadaxawaaraha:0-45m/min. 6) Korontada: 380V, 50HZ,3 waji 7) Wadarta awooda qalabka:70KW. |

| 2 | Uqalab wax qabad | 1)Φ60Hagaha birta aan birta lahayn duuduubka. 2) Gear Drive + biriiga budada magnetic + kontoroolka. 3) Qalabka hagaajinta weecaashiyaha. 4) Φ74 shafka la buufiyo. |

| 3 | Qalabka wareejinta xabagta | 1)Φ60 Duubabka hagaha birta aan-lahayn. 2)Φ240 Duubabka birta ah. 3)Φ150 duub aluminium aluminium ah. 4)Φ200 Silikoon rullaluistem ah. 5)Φ160 roller dhinac Silikoon. 6)Φ80 dhululubo la hagaajin karo. 7)Φ63 dhululubo la hagaajin karo. 8) Qaybaha pneumatic. 9) Pendulum matoor yar + beddelka soo noqnoqda. 10) Xoq-xaq + xoqid. 11) Aluminium furan oo firfircoon. |

| 4 |

Quudinta dhabarka+Aalad si toos ah u furaysa iyo hagaajinta | 1)Φ60 birta aan daahinsoo rogo. 2)Φ60 Duubabka hagaha birta aan-lahayn. 3)Φ108 Gacan-qaade suunka. 4) suunka qaade hagaha. 5) Matoorka lulida + beddelka. 6) Qalab sax ah oo sambabada sambabada ah. 7) Qalabka dabaysha ee fiilada. 8) Aluminium furan oo firfircoon. 9) Bambada + fidinta geesaha. 10)Qaybaha pneumatic. |

| 5 | Qalajinta qalabka wax lagu dhejiyo ee dhululubada | 1) φ1500 foornada kuleylka korontada. 2) φ150 silikoon roller. 3) φ60 Hagaha birta aan birta lahayn roll. 4) Tuubada kululaynta korontada. 5) Silinder. 6) Qalabka xakamaynta heerkulka. 7)Qaybaha pneumatic. |

| 6 | Qalabka qaboojinta | 1) φ60 Hagaha birta aan birta lahaynl. 2) φ150 roller. 3) φ500 qaboojinta rullaluistemadka birta. 4) Qaboojinta wadajirka wareegga wareegga biyaha + tuubada birta. 5) Silinder. 6) Wad + tallaabo ka-hortagga xawaarihiisa ka yar + sanduuqa marshada gadaal. |

| 7 | Qalabka goynta cidhifyada | 1) Makiinada goynta + matoorka. 2) Qalabka wax-ka-beddelka cabbirka-gooyaha. 3) Pump + nuugista geesaha. 4) φ60 Duubabka hagaha birta aan-ahmaahda lahayn. |

| 8 | Qalabka jiidista | 1) φ60 Duubabka hagaha birta aan-ahmaahda lahayn. 2) φ120 duub. 3) φ124 Duubista rullaluistemadka birta. 4) Silinder. 5) Qalabka mitirka + taageerada. |

| 9 | Qalabka dib u laabashada | 1) duub aluminium ah. 2) φ215 duudduuban gariiradda birta. 3) Pendulum matoor yar + beddelka soo noqnoqda. |

| 10 | Mashiinkarinjiyeyn | 1) Putty. 2) Kahortagga daxalka. 3) Rinjiga dusha sare (Customredized). |

Si Balaadhan Loo Isticmaalay

FAQ

Waa maxay mishiinka dahaadhida?

Guud ahaan, mishiinka wax lagu dhejiyo waxaa loola jeedaa qalabka wax lagu dhejiyo kaas oo si weyn loogu isticmaalo dharka guriga, dharka, alaabta guriga, gudaha baabuurta iyo warshadaha kale ee la xiriira.

Waxaa inta badan loo isticmaalaa laba-lakab ama multi-lakab habka wax soo saarka bond bonding ee dhar kala duwan, maqaar dabiiciga ah, maqaar artifical, filim, warqad, isbuunyo, xumbo, PVC, EVA, filim khafiif ah, iwm.

Gaar ahaan, waxa loo kala qaybiyaa xabagta xabagta iyo laminating non-dhesive, iyo laminating xabaggu waxa loo qaybiyaa koollada biyaha ku salaysan, xabagta saliidda PU, xabagta dareeraha ku salaysan, xabagta xasaasiga ah ee cadaadiska, xabagta super, xabagta kulul, iwm. Habka laminating inta badan waa isku xidhka kulaylka tooska ah ee ka dhexeeya alaabta ama daahyada ololka.

Mashiinadayadu waxay kaliya sameeyaan habka Lamination.

Qalabkee ku habboon laminating?

(1) Maro leh dhar: dhar tolan iyo tolmo, aan tolmo lahayn, funaanad, dhogorta, nylon, Oxford, Denim, Velvet, plush, dharka suede, interlinings, polyester taffeta, iwm.

(2) Maro leh filimaan, sida filimka PU, filimka TPU, filimka PTFE, filimka BOPP, filimka OPP, filimka PE, filimka PVC ...

(3) Harag, maqaar la sameeyay, isbuunyo, xumbo, EVA, caag....

Warshadee u baahan tahay iyadoo la isticmaalayo mashiinka dharka lagu dhejiyo?

Mashiinka laminating oo si ballaaran loogu isticmaalo dhameynta dharka, moodada, kabaha, koofiyadaha, bacaha iyo shandadadaha, dharka, kabaha iyo koofiyadaha, boorsooyinka, dharka guriga, gudaha baabuurta, qurxinta, baakadaha, abrasives, advertising, sahayda caafimaadka, alaabta nadaafadda, qalabka dhismaha, alaabta lagu ciyaaro , Dharka warshadaha, alaabta shaandhada deegaanka u fiican iwm.

Sidee loo doortaa mashiinka dharka lagu dhejiyo ee ugu habboon?

A. Waa maxay shuruudaha xalinta agabka tafatiran?

B. Waa maxay sifooyinka walxaha ka hor inta aan laminating?

C. Waa maxay isticmaalka alaabtaada dahaaran?

D. Waa maxay sifooyinka maadiga ah ee aad u baahan tahay si aad u gaadho ka dib markii la nadiifiyo?

Sideen u rakibi karaa ugana shaqayn karaa mishiinka?

Waxaan bixinaa tilmaamo Ingiriis ah oo faahfaahsan iyo fiidiyowyo hawlgal ah.Ingineerku waxa kale oo uu u bixi karaa dibadda si uu u rakibo mishiinka oo uu u tababaro shaqaalahaaga si ay u shaqeeyaan.

Miyaan arkaa mishiinka oo shaqaynaya ka hor intaan la dalban?

Ku soo dhawoow saaxiibada adduunka oo dhan si ay u soo booqdaan warshadeena wakhti kasta.