Mucheka wekugadzira laminating muchina

Zvakanakira zvemuchina wedu ndeye gravure roll pamusoro pe laminating muchina unogona kugadziridzwa ne laser kuita akasiyana mapatani, ayo anogona kuve nechokwadi chekuti dhizaini yekunamira inoramba yakavhurika kana kusaenderera, kudzivirira kunamira kufashukira mu laminating process, musimboti we gravure roller ndeye. zvakafanana nehunyanzvi hwekudhinda, yakanaka pateni dhizaini ye gravure roller inogona kuita kuti machira apfeke uye laminating ave zvakanaka.Xinlilong Technology inopa akatevedzana gravure roller's pateni dhizaini, iyo inogona kubatsira vatengi kusarudza yake yekutanga kana nyowani gravure roller yemuchina wekuisa laminating, uchangotengwa kubva kwatiri.

Chimiro

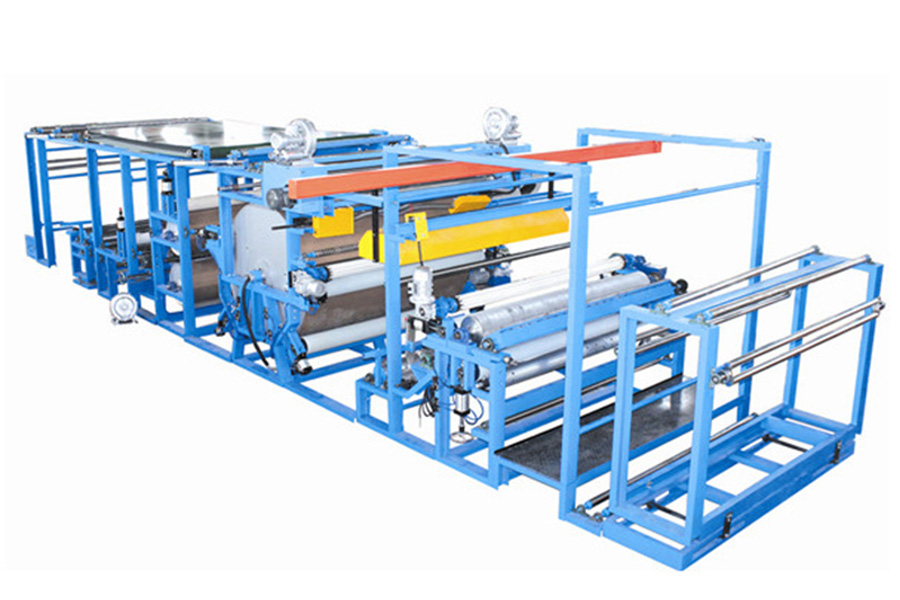

Mucheka kune Fabric Laminating Machine

1. Inoshandiswa kubatanidza uye kuramisa mucheka, nonwoven, textile, waterproof, mafirimu anofema uye nezvimwe.

2. Kubatsirwa nePLC chirongwa chekutonga uye man-machine touch interface, nyore kushanda.

3. Yepamberi yekumisikidza uye scothing zvishandiso, muchina uyu unowedzera dhigirii reotomatiki, unochengetedza mutengo wevashandi, unorerutsa kusimba kwevashandi, uye unosimudzira kugadzirwa kwakanaka.

4. Ne PU glue kana solvent based glue, zvigadzirwa zvakasvibiswa zvine pfuma yakanaka yekunamatira uye kubata zvakanaka.Iwo anogona kugezwa uye akaoma-akachena.Nekuda kweglue iri muchimiro chepfungwa kana laminating, zvigadzirwa zvelaminated zvinofema.

5. Inoshanda kutonhora mudziyo inosimudzira lamination maitiro.

6. Sewing cutter inoshandiswa kucheka michero yakasvibirira yezvinhu laminated.

Laminating Materials

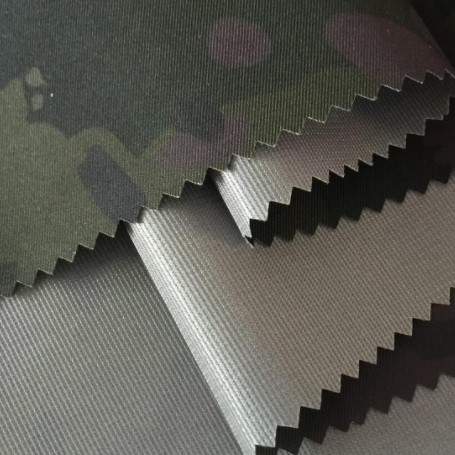

1.Fabric + jira: machira, jersey, mvere, Nylon, Velvet, Terry jira, Suede, nezvimwewo.

2.Fabric + mafirimu, akadai sePU film, TPU film, PE film, PVC film, PTFE film, etc.

3.Fabric+ Leather/Artificial Leather, nezvimwewo.

4.Fabric + Nonwoven

5.Sponge/ Foam neFabric/ Artificial Leather

Main Technical Parameters

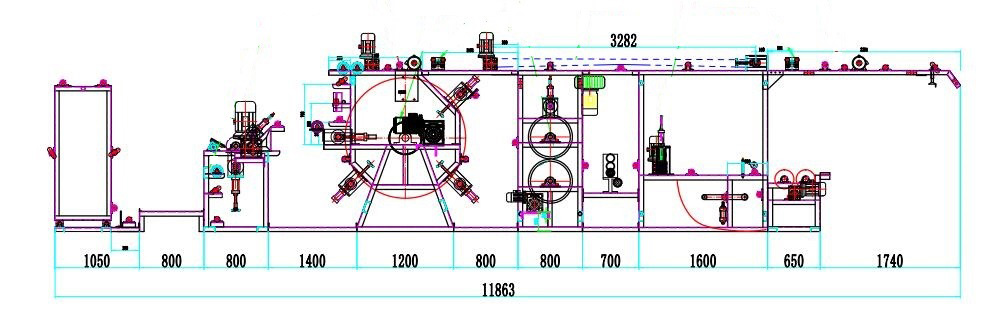

| Aihwa. | Zvikamu Zvikuru | DetailTsanangudzos |

| 1 | Main technical parameters | 1) Roller yakafara ndeye 1800mm, einoshandalaminating widthiri 1600mm. 2) Kunyanya kune laminating machira ne machira,isina-kurukwazvinhu,nezvimwe zvinyoro zvinyoro etc. 3) Gluing nzira: glue kutamisaed ne gluing roller. 4) Heating nzira:Magetsi. 5) Basaing speed:0-45m/min. 6) Simba rekupa: 380V, 50HZ,3 phase. 7) Total equipment power:70KW. |

| 2 | Umhepo mudziyo | 1)Φ60Stainless simbi inotungamira roll+Bearing. 2) Gear drive + magnetic poda brake + controller. 3) Hydraulic kutsauka kugadzirisa mudziyo. 4) Φ74 Inflatable shaft. |

| 3 | Glue transfer set | 1)Φ60 Stainless simbi inotungamira roll roll. 2)Φ240 Stainless simbi roll. 3)Φ150 Aluminium alloy roll. 4)Φ200 Silicon roller. 5)Φ160 Silicone side roller. 6)Φ80 Humburumbira inogadziriswa. 7)Φ63 Humburumbira inogadziriswa. 8) Pneumatic components. 9) Pendulum shoma mota + frequency converter. 10) Scraper + scraper furemu. 11) Active aluminium kuvhura mudziyo. |

| 4 |

Kudzosera kumashure + Kuvhura otomatiki uye kugadzirisa mudziyo | 1)Φ60 Simbi isina tsvinabata roll. 2)Φ60 Stainless simbi inotungamira roll roll. 3)Φ108 Conveyor belt roller. 4) Nhungamiro conveyor bhandi. 5) Swing mota + inverter. 6) Pneumatic kutsauka kugadzirisa mudziyo. 7) Wire winding device. 8) Active aluminium yakavhurika mudziyo. 9) Pombi + edge spreader. 10)Pneumatic components. |

| 5 | Kuomesa humburumbira laminating mudziyo | 1) φ1500 Magetsi kupisa ovheni. 2) φ150 Silicone roller. 3) φ60 Stainless simbi inotungamira roll. 4) Magetsi ekupisa chubhu. 5) Cylinder. 6) Temperature control device. 7)Pneumatic components. |

| 6 | Kutonhodza mudziyo | 1) φ60 Stainless simbi inotungamira rolll. 2) φ150 Rubber roller. 3) φ500 Kutonhora simbi roller. 4) Mvura inotonhorera inotenderera yakabatana + simbi hose. 5) Cylinder. 6) Dhiraivha + nhanho shoma yekumhanyisa regulator + reverse giya bhokisi. |

| 7 | Edge yekucheka mudziyo | 1) Bowl cutter + mota. 2) Cutter amplitude modulation mudziyo. 3) Pombi + mupendero wemupendero. 4) φ60 Stainless simbi inotungamira roll. |

| 8 | Towing mudziyo | 1) φ60 Stainless simbi inotungamira roll. 2) φ120 Rubber roll. 3) φ124 Plating simbi roller. 4) Cylinder. 5) Meter mudziyo + rutsigiro. |

| 9 | Rewinding set | 1) Aluminium roll. 2) φ215 simbi coiling roll. 3) Pendulum shoma mota + frequency converter. |

| 10 | Machinekupenda | 1) Putty. 2) Anti-ngura primer. 3) Pendi yepamusoro (Yakagadzirirwa). |

Inoshandiswa Zvakawanda In

FAQ

Chii chinonzi laminating machine?

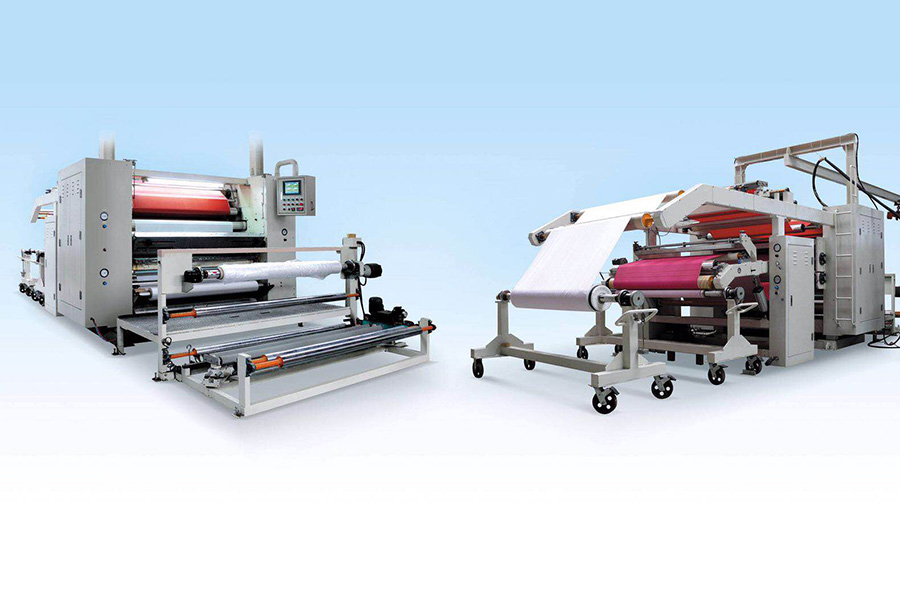

Kazhinji kutaura, muchina wekuchemedza unoreva mudziyo welamination uyo unoshandiswa zvakanyanya mumachira epamba, zvipfeko, fenicha, zvemukati zvemotokari uye mamwe maindasitiri ane hukama.

Inonyanya kushandiswa kune maviri-layer kana akawanda-layer bonding maitiro ekugadzira akasiyana machira, echisikigo dehwe, artifical dehwe, firimu, bepa, chipanje, furo, PVC, EVA, nhete firimu, nezvimwewo.

Kunyanya, iyo yakakamurwa kuita adhesive laminating uye isina-adhesive laminating, uye adhesive laminating yakakamurwa kuva mvura based glue, PU mafuta adhesive, solvent-based glue, pressure sensitive glue, super glue, hot melt glue, etc. Iyo isina-adhesive laminating process inonyanya kunanga thermocompression bonding pakati pezvinhu kana flame combustion lamination.

Michina yedu inongogadzira Lamination process.

Ndezvipi zvinhu zvakakodzera laminating?

(1) Mucheka une jira: machira akarukwa uye akarukwa, asina kuruka, jezi, mvere, Nylon, Oxford, Denim, Velvet, plush, suede jira, interlinings, polyester taffeta, nezvimwewo.

(2) Micheka ine mafirimu, sePU firimu, TPU firimu, PTFE firimu, BOPP firimu, OPP firimu, PE firimu, PVC firimu...

(3) Leather, Synthetic dehwe, Sponge, Foam, EVA, Plastic....

Ndeipi indasitiri inoda kushandisa laminating muchina?

Laminating muchina unoshandiswa zvakanyanya mukupedzisa machira, fashoni, shangu, cap, mabhegi uye masutukesi, zvipfeko, shangu neheti, mikwende, machira epamba, zvemukati zvemotokari, kushongedza, kurongedza, abrasives, kushambadzira, zvekurapa, zvigadzirwa zvehutsanana, zvekuvakisa, matoyi. , machira emaindasitiri, zvakatipoteredza zvine hushamwari sefa zvinhu nezvimwe.

Nzira yekusarudza sei yakakodzera laminating muchina?

A. Chii chinodiwa chekugadzirisa zvinhu?

B. Ndeapi maitiro ezvinyorwa asati laminating?

C. Ndeipi kushandiswa kwezvigadzirwa zvako zvelaminated?

D. Ndezvipi zvinhu zvenyama zvaunoda kuti uwane mushure mekucheka?

Ndingaite sei kuisa nekushandisa muchina?

Isu tinopa yakadzama yekuraira kweChirungu uye mavhidhiyo ekushanda.Injiniya inogona zvakare kuenda kunze kwenyika kufekitori yako kuisa muchina uye kudzidzisa vashandi vako kushanda.

Ndoona muchina uchishanda usati warongeka?

Gamuchira shamwari pasi rese kuti shanyira fekitori yedu chero nguva.