Top Suppliers Solvent Free Pu Glue Film Laminating Machine - Fabric to foam laminating machine – Xinlilong

Top Suppliers Solvent Free Pu Glue Film Laminating Machine - Fabric to foam laminating machine – Xinlilong Detail:

Our laminating capabilities also include hot melt laminating, flame laminating, and pressure-sensitive adhesive laminating, heat press laminating. We will also work with our customers to thoroughly understand the functional requirements of their special applications in order to determine which lamination process will provide the necessary functionality of the composite, and which process will be the most Environmental friendly & cost-effective.

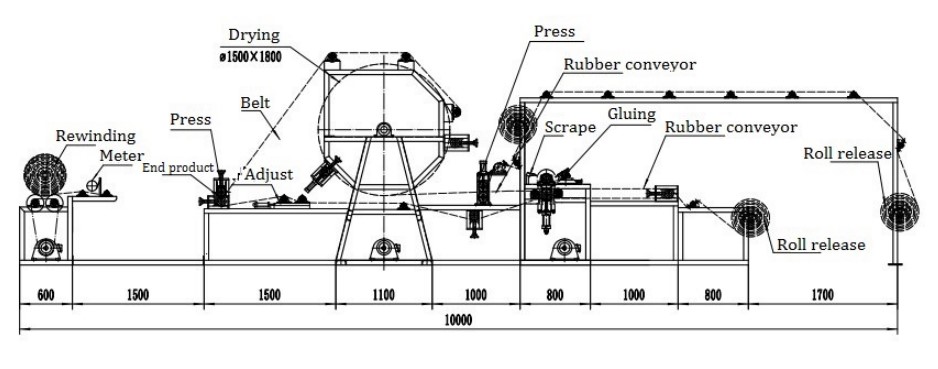

Structure

Laminating Machine Features

1. It uses water-based glue.

2. Improve the quality of the products greatly, save cost.

3. Vertical or horizontal structure, low breakdown rate and long service time.

4. Equipped with high quality heat resistance net belt to make the laminated materials contact closely with the drying cylinder, to improve the drying effect, and make the laminated product soft, washable, and strengthen adhesive fastness.

5. This laminating machine has two sets of heating system, user can select one set heating mode or two sets, to reduce the energy consumption and lower costs.

6. Surface of heating roller is coated with Teflon in order to efficacious prevent the hot melt adhesive against sticking on the surface of roller and carbonization.

7. For clamp roller, both hand wheel adjustment and the pneumatic control are available.

8. Equipped with automatic infrared centering control unit, which can effectively prevent the net belt deviation, and ensure the net belt service life.

9. Customized manufacturing is available.

10. Low maintenance cost and simple to maintain.

Main Technical Parameters

|

Heating method |

Electric heating/Oil heating/Steam heating |

|

Diameter (Machine Roller) |

1200/1500/1800/2000mm |

|

Working Speed |

5-45m/min |

|

Heating Power |

40kw |

|

Voltage |

380V/50HZ, 3 phase |

|

Measurement |

7300mm*2450mm2650mm |

|

Weight |

3800kg |

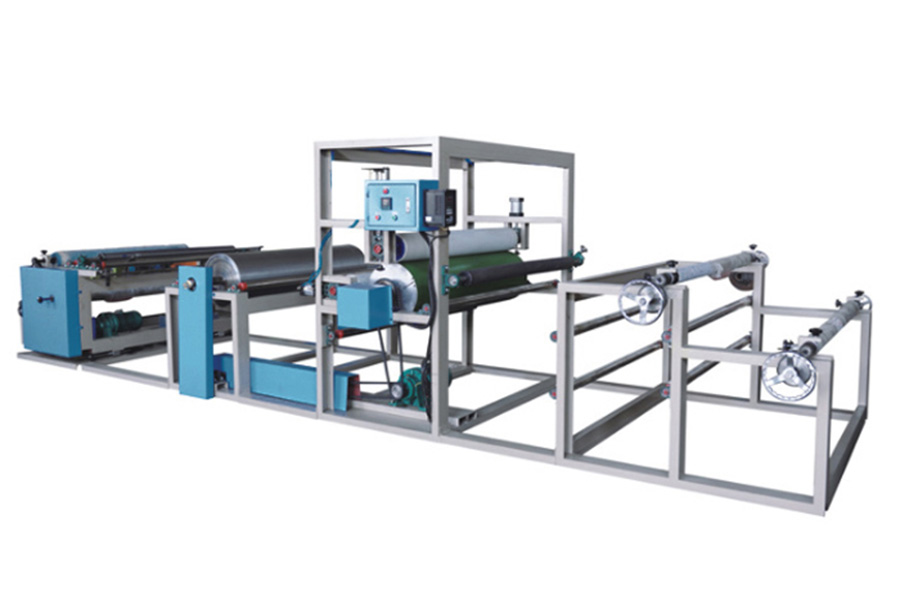

Product detail pictures:

Related Product Guide:

Which has a positive and progressive attitude to customer's desire, our corporation constantly improves our merchandise quality to satisfy the desires of consumers and further focuses on safety, reliability, environmental demands, and innovation of Top Suppliers Solvent Free Pu Glue Film Laminating Machine - Fabric to foam laminating machine – Xinlilong , The product will supply to all over the world, such as: Italy, Congo, India, We have a good reputation for stable quality products, well received by customers at home and abroad. Our company would be guided by the idea of "Standing in Domestic Markets, Walking into International Markets". We sincerely hope that we could do business with car manufacturers, auto part buyers and the majority of colleagues both at home and abroad. We expect sincere cooperation and common development!

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!