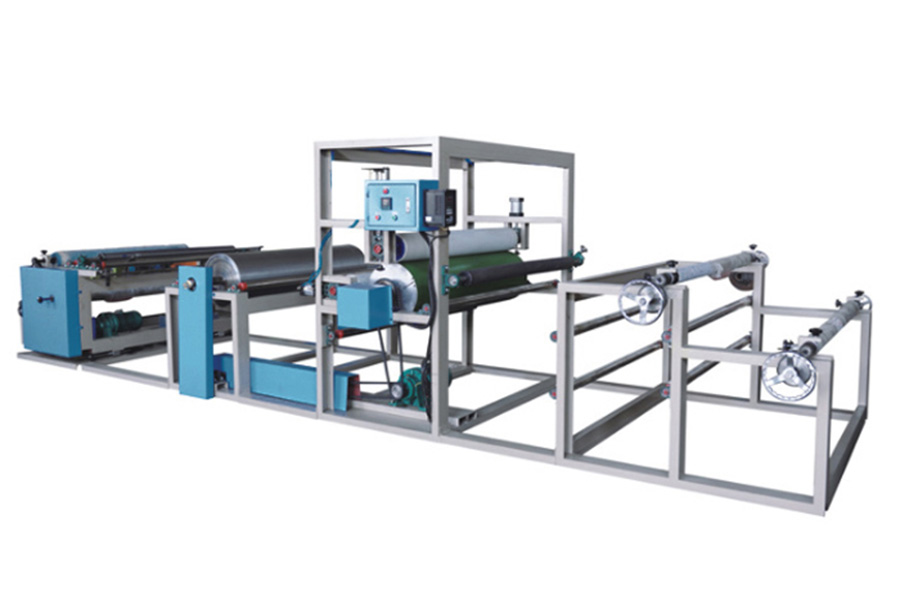

Plywood Laminating Machine - Flame spraying bonding machine – Xinlilong

Plywood Laminating Machine - Flame spraying bonding machine – Xinlilong Detail:

By flame lamination making the compound of two or three layers. There have three components (single, resp. sandwich-lamination) by using the adhesion characteristics of the foam which is melted by the line gas burner.

Flame laminating machine are used to join thermoplastic materials like foam made of polyester, polyether, polyethylene or various adhesive foils and textile, PVC-foils, artificial leather, non-wovens, papers or other materials.

Depending on the machine construction, single or sandwich laminations can be made. The materials are taken from bales or plates.

A line gas burner, which is installed across the whole working width, is melting the foam, resulting in an adhesive film. Inside the calender, the foam and the top fabric, resp. the backlining, are permanently joined together when running through the laminating gap.

Flame Lamination Machine Features

1. It adopts advanced PLC, touch screen and servo motor control, with good synchronization effect, no tension automatic feeding control, high continuous production efficiency, and the sponge table is used to be uniform, stable and not elongated.

2. The three-layer material can be combined in one time through the double-fired simultaneous combustion, which is suitable for mass production. Domestic or imported fire platoons can be selected according to the product requirements.

3. The composite product has the advantages of strong overall performance, good hand feeling, water washing resistance and dry cleaning.

4. Special requirements can be customized as needed.

Main Technical Parameters

|

Burner Width |

2.1m or customised |

|

Burning Fuel |

Liquefied natural gas (LNG) |

|

Laminating speed |

0~45m/min |

|

Cooling method |

water cooling or air cooling |

Widely Used In

Automotive industry (interiors and seats)

Furniture industry (chairs, sofas)

Footwear industry

Garment industry

Hats, gloves,bags, toys and etc

Characteristics

1. Gas Type: Natural Gas or Liquefied Gas.

2. The water cooling system well enhances the lamination effect.

3. The air exhaust diaphragm will exhaust the odor.

4. Fabric spreading device is installed to make the laminated material smooth and neat.

5. The strength of the bonding depends on the material and the foam or EVA selected and the processing conditions.

6. With high integrity and long term adhesive durability, the laminated materials touch well and is dry washable.

7. Edge tracker, tensionless fabric unwinding device, stamping device and other auxiliary equipment can be optionally installed.

Product detail pictures:

Related Product Guide:

We now have a highly efficient crew to deal with inquiries from clients. Our intention is "100% shopper pleasure by our merchandise quality, price tag & our staff service" and take pleasure in a very good standing amongst purchasers. With quite a few factories, we can easily provide a wide vary of Plywood Laminating Machine - Flame spraying bonding machine – Xinlilong , The product will supply to all over the world, such as: South Africa, Malta, Suriname, Our company has built stable business relationships with many well-known domestic companies as well as oversea customers. With the goal of providing high quality products to customers at low cots, we've been committed to improving its capacities in research, development, manufacturing and management. We have honored to receive recognition from our customers. Till now we have now passed ISO9001 in 2005 and ISO/TS16949 in 2008. Enterprises of "quality of survival, the credibility of development" for the purpose, sincerely welcome domestic and foreign businessmen to visit to discuss cooperation.

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!