One of Hottest for Pur Hot Melt Glue Film Laminating Machine - Fabric to foam laminating machine – Xinlilong

One of Hottest for Pur Hot Melt Glue Film Laminating Machine - Fabric to foam laminating machine – Xinlilong Detail:

Our laminating capabilities also include hot melt laminating, flame laminating, and pressure-sensitive adhesive laminating, heat press laminating. We will also work with our customers to thoroughly understand the functional requirements of their special applications in order to determine which lamination process will provide the necessary functionality of the composite, and which process will be the most Environmental friendly & cost-effective.

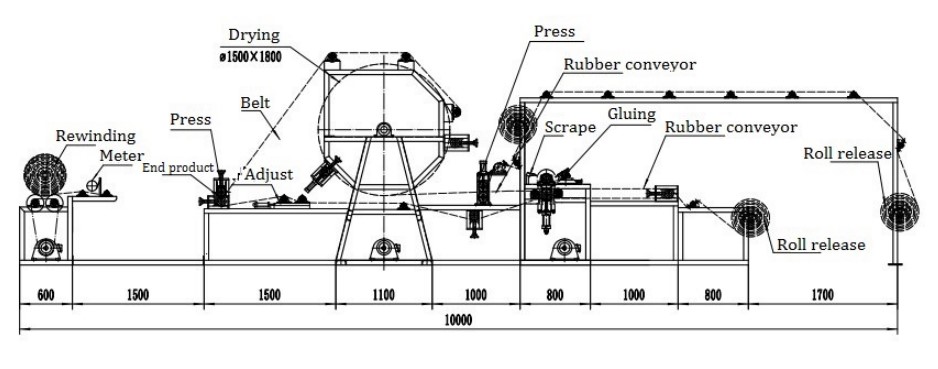

Structure

Laminating Machine Features

1. It uses water-based glue.

2. Improve the quality of the products greatly, save cost.

3. Vertical or horizontal structure, low breakdown rate and long service time.

4. Equipped with high quality heat resistance net belt to make the laminated materials contact closely with the drying cylinder, to improve the drying effect, and make the laminated product soft, washable, and strengthen adhesive fastness.

5. This laminating machine has two sets of heating system, user can select one set heating mode or two sets, to reduce the energy consumption and lower costs.

6. Surface of heating roller is coated with Teflon in order to efficacious prevent the hot melt adhesive against sticking on the surface of roller and carbonization.

7. For clamp roller, both hand wheel adjustment and the pneumatic control are available.

8. Equipped with automatic infrared centering control unit, which can effectively prevent the net belt deviation, and ensure the net belt service life.

9. Customized manufacturing is available.

10. Low maintenance cost and simple to maintain.

Main Technical Parameters

|

Heating method |

Electric heating/Oil heating/Steam heating |

|

Diameter (Machine Roller) |

1200/1500/1800/2000mm |

|

Working Speed |

5-45m/min |

|

Heating Power |

40kw |

|

Voltage |

380V/50HZ, 3 phase |

|

Measurement |

7300mm*2450mm2650mm |

|

Weight |

3800kg |

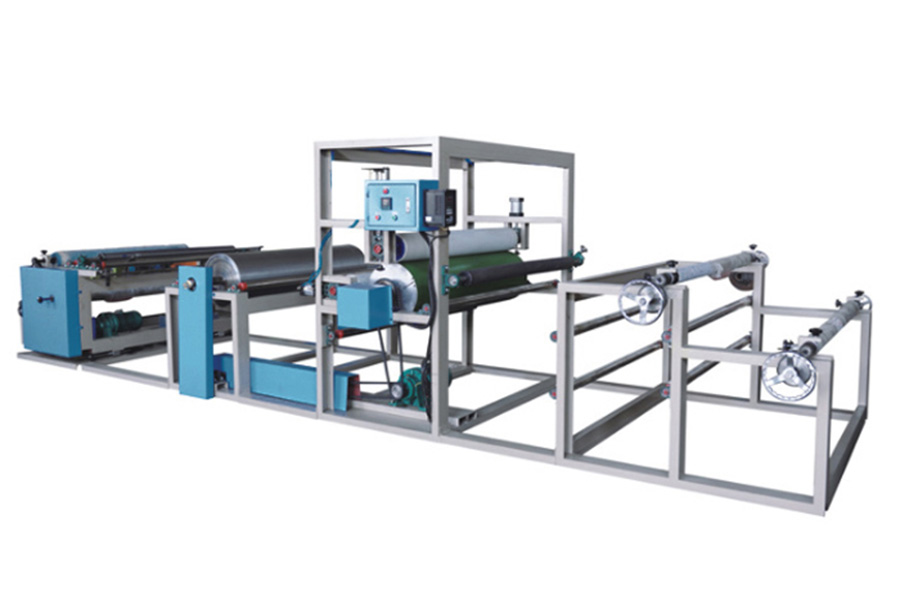

Product detail pictures:

Related Product Guide:

To meet the customers' over-expected gratification , we have our robust crew to offer our best over-all support which includes marketing, income, coming up with, production, excellent managing, packing, warehousing and logistics for One of Hottest for Pur Hot Melt Glue Film Laminating Machine - Fabric to foam laminating machine – Xinlilong , The product will supply to all over the world, such as: Wellington, Salt Lake City, Guatemala, Due to our good goods and services, we've received good reputation and credibility from local and international customers. If you will need more information and are interested in any of our solutions, be sure to feel free to contact us. We look forward to becoming your supplier in the near future.

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!