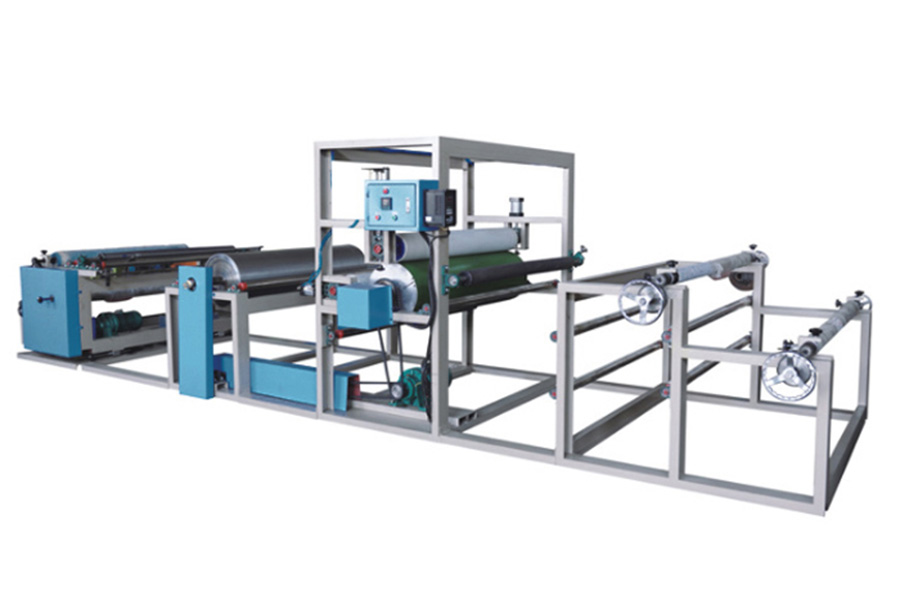

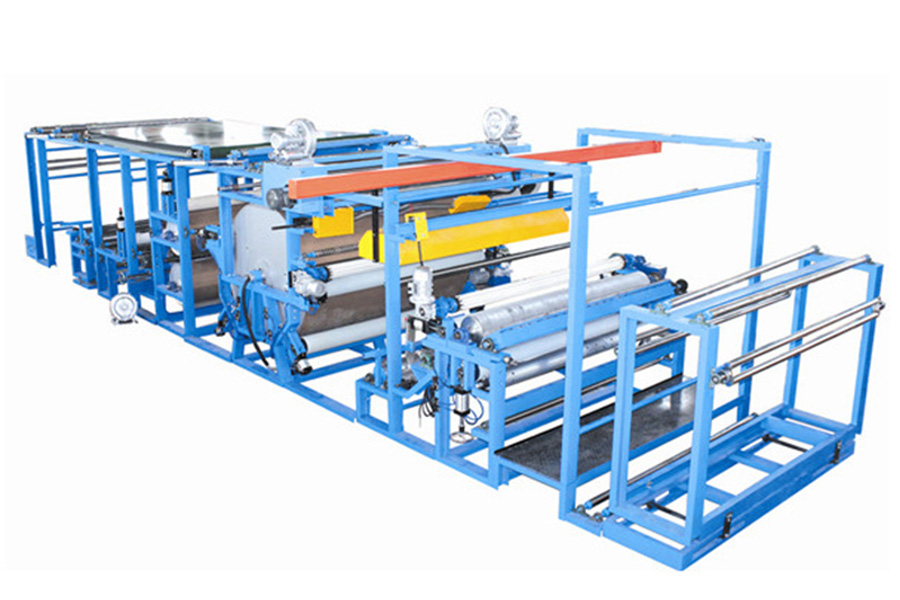

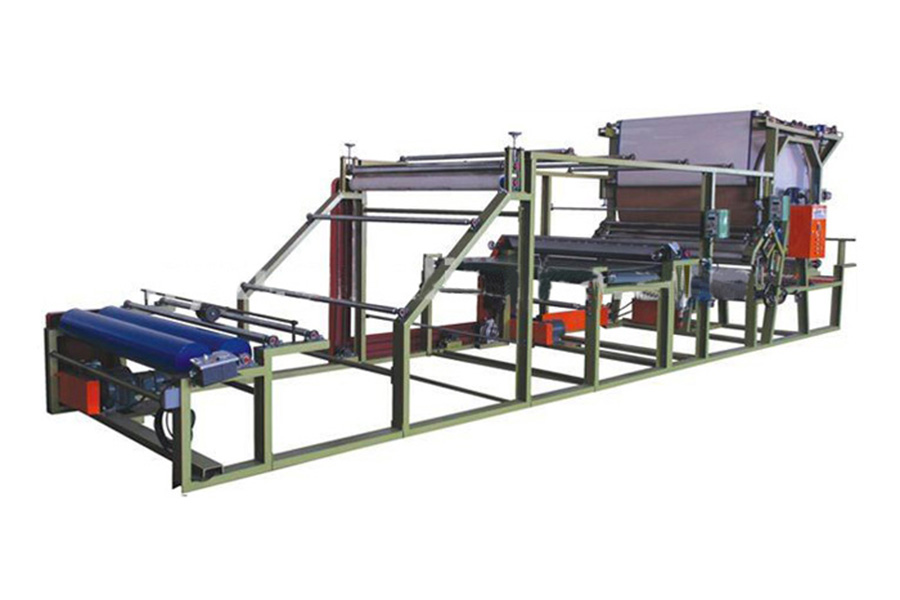

OEM/ODM Manufacturer Oil-Based Glue Lamination Machine - Shoe making material laminating machine – Xinlilong

OEM/ODM Manufacturer Oil-Based Glue Lamination Machine - Shoe making material laminating machine – Xinlilong Detail:

The shoe making material is mainly composed of the following five parts

1.Leather.

Leather is flexible yet durable, as sturdy as it is supple. It’s elastic, so it can be stretched yet it resists tearing and abrasion.

2.Textiles.

Fabric is also quite commonly used for making shoes. Like leather, textiles are available in a wide array of colors and varieties.

3.Synthetics.

Synthetic materials go by many different names– PU leather or simply PU, synthetic leather or simply synthetics– but they’re all the same in being man-made composites of two.

4.Rubber.

Rubber is most commonly used in shoes to make soles.

5.Foam.

Foam is the most common material used to provide support in the uppers of shoes of all sorts, be they leather, textile, synthetic or even rubber.

Laminating Machine Features

1.It uses water-based glue.

2.Improve the quality of the products greatly, save cost.

3. Vertical or horizontal structure, low breakdown rate and long service time.

4. The material feeding roller is driven by air cylinder, realizing more rapid, convenient and precise process.

5. Equipped with high quality heat resistance net belt to make the laminated materials contact closely with the drying cylinder, to improve the drying and bonding effect, and make the laminated product soft, washable, and strengthen adhesive fastness.

6. There is a glue scraping blade to scrape the glue evenly onto fabric and the unique glue channel design facilitates the cleaning of the glue after lamination.

7. This laminating machine has two sets of heating system, user can select one set heating mode or two sets, to reduce the energy consumption and lower costs.

8. Surface of heating roller is coated with Teflon in order to efficacious prevent the hot melt adhesive against sticking on the surface of roller and carbonization.

9. For clamp roller, both hand wheel adjustment and the pneumatic control are available.

10. Automatic infrared centering control unit effectively prevents the net belt deviation and prolongs the net belt service lifespan.

11. All the heating pipes in the drying roller are made of stainless steel and the temperature of the heating drying roller can be as high as 160 celcius degree, and even 200 celcius degree. There are usually two sets of heating system in the drying roller. The heating will automatically change from one set to two sets. It is safe and energy saving.

12. Counting device and rewinding device are installed on the machine.

It is simple to maintain the machine and the maintenance cost is low.

13. Equipped with automatic infrared centering control unit, which can effectively prevent the net belt deviation, and ensure the net belt service life.

14. Customized manufacturing is available.

15. Low maintenance cost and simple to maintain.

Main Technical Parameters

|

Heating method |

Electric heating/Oil heating/Steam heating |

|

Diameter (Machine Roller) |

1200/1500/1800/2000mm |

|

Working Speed |

5-45m/min |

|

Heating Power |

40kw |

|

Voltage |

380V/50HZ, 3 phase |

|

Measurement |

7300mm*2450mm2650mm |

|

Weight |

3800kg |

FAQ

What’s the laminating machine?

Generally speaking, the laminating machine refers to a lamination equipment which is widely used in home textiles, garments, furniture, automotive interiors and other related industries.

It is mainly used for two-layer or multi-layer bonding production process of various fabrics, natural leather, artifical leather, film, paper, sponge, foam, PVC, EVA, thin film,etc.

Specifically, it is divided into adhesive laminating and non-adhesive laminating, and adhesive laminating is divided into water based glue, PU oil adhesive, solvent-based glue, pressure sensitive glue, super glue, hot melt glue, etc. The non-adhesive laminating process is mostly direct thermocompression bonding between materials or flame combustion lamination.

Our machines only make Lamination process.

Which materials are suitable for laminating?

(1) Fabric with fabric: knitted fabrics and woven, non-woven, jersey, fleece, Nylon, Oxford, Denim, Velvet, plush,suede fabric,interlinings, polyester taffeta ,etc.

(2) Fabric with films, like PU film, TPU film, PTFE film, BOPP film, OPP film, PE film, PVC film…

(3) Leather, Synthetic leather, Sponge, Foam, EVA, Plastic….

Which industry need using the laminating machine?

Laminating machine widely used in textile finishing, fashion, footwear, cap, bags and suitcases, clothing, shoes and hats, luggage, home textiles, automotive interiors, decoration, packaging, abrasives, advertising, medical supplies, sanitary products, building materials, toys, industrial fabrics, environmentally friendly filter materials etc.

How to choose the most suitable laminating machine?

A. What’s the detail material solution requirement?

B. What ‘s the material’s characteristics before laminating?

C. What’s the usage of your laminated products?

D. What’s the material properties do you need to achieve after lamination?

How can I install and operate the machine?

We offer detailed English instruction and operation videos. Engineer can also go abroad to your factory to install the machine and traning your staff to operation.

Shall I see the machine working before order?

Welcome friends around the world to visit our factory for any time.

Product detail pictures:

Related Product Guide:

We usually perform being a tangible workforce making sure that we will give you the most beneficial excellent plus the finest selling price for OEM/ODM Manufacturer Oil-Based Glue Lamination Machine - Shoe making material laminating machine – Xinlilong , The product will supply to all over the world, such as: Malaysia, Provence, Albania, If you are for any reason unsure which product to select, do not hesitate to contact us and we are going to be delighted to advise and assist you. This way we are going to be providing you with all the knowledge needed to make the best choice. Our company strictly follows "Survive by good quality, Develop by keeping good credit. " operation policy. Welcome all the clients old and new to visit our company and talk about the business. We have been looking for more and more customers to create the glorious future.

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.