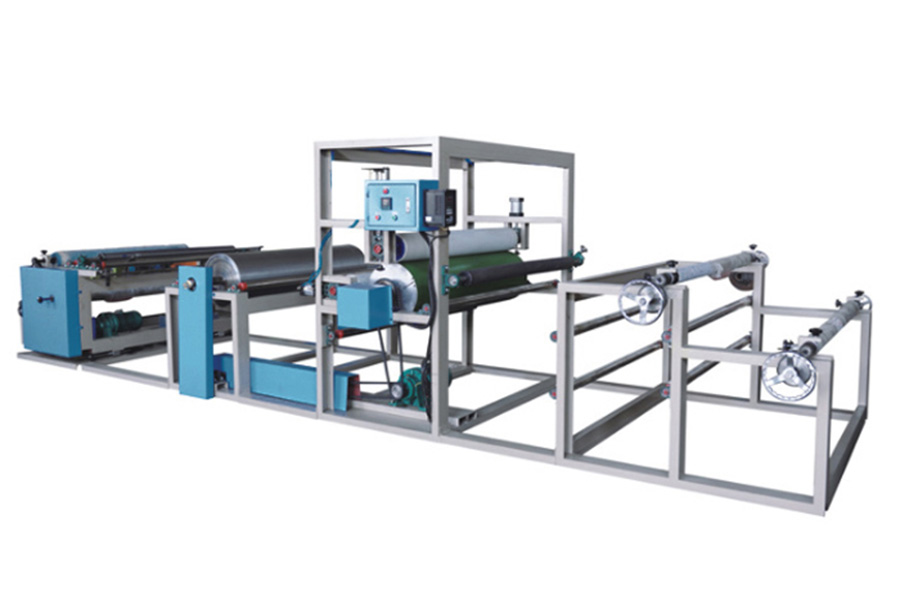

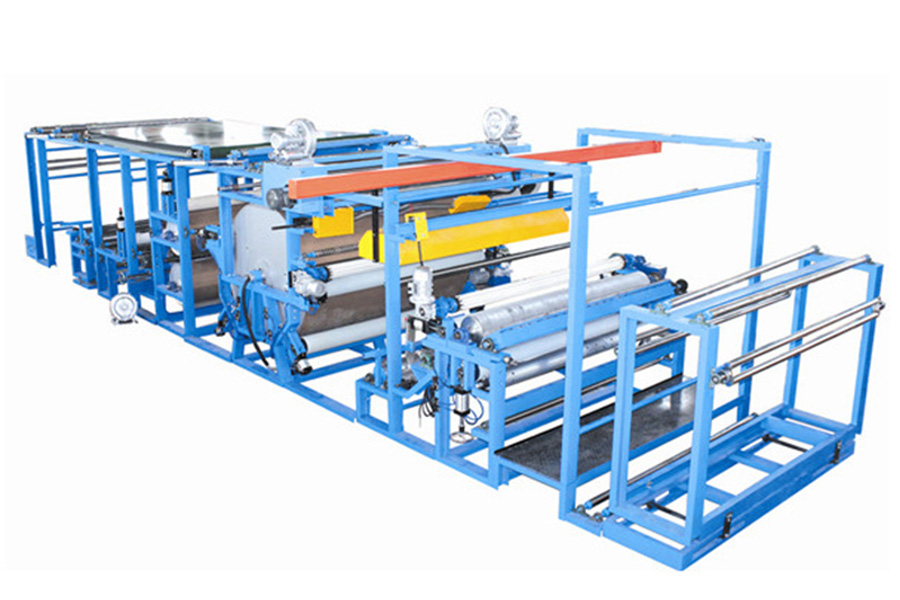

OEM/ODM China Plastic/Pe Foam Sheet Laminating Machine - Kraft paper tape coating machine – Xinlilong

OEM/ODM China Plastic/Pe Foam Sheet Laminating Machine - Kraft paper tape coating machine – Xinlilong Detail:

Mainly for producing Adhesive Label, Double Side Tape, Foam Tape, Duct Tape, Kraft Paper Tape, Masking Tape, Fiber Tape etc.

Main Technical Parameters

|

Effective Fabrics Width |

1000~1700mm/Customized |

|

Roller Width |

1800mm/Customized |

|

Production speed: |

0~30 m/min |

|

Demension (L*W*H): |

15950×2100×3600 mm |

|

Gross Power |

About 105KW |

|

Voltage |

380V 50HZ 3Phase / customizable |

|

Weight |

About 11340KG |

Widely Used In

PET, POL, PVA, Release paper and polyurethane film such as TAC.

FAQ

What’s the laminating machine?

Generally speaking, the laminating machine refers to a lamination equipment which is widely used in home textiles, garments, furniture, automotive interiors and other related industries.

It is mainly used for two-layer or multi-layer bonding production process of various fabrics, natural leather, artifical leather, film, paper, sponge, foam, PVC, EVA, thin film,etc.

Specifically, it is divided into adhesive laminating and non-adhesive laminating, and adhesive laminating is divided into water based glue, PU oil adhesive, solvent-based glue, pressure sensitive glue, super glue, hot melt glue, etc. The non-adhesive laminating process is mostly direct thermocompression bonding between materials or flame combustion lamination.

Our machines only make Lamination process.

Which materials are suitable for laminating?

(1) Fabric with fabric: knitted fabrics and woven, non-woven, jersey, fleece, Nylon, Oxford, Denim, Velvet, plush,suede fabric,interlinings, polyester taffeta ,etc.

(2) Fabric with films, like PU film, TPU film, PTFE film, BOPP film, OPP film, PE film, PVC film…

(3) Leather, Synthetic leather, Sponge, Foam, EVA, Plastic….

Which industry need using the laminating machine?

Laminating machine widely used in textile finishing, fashion, footwear, cap, bags and suitcases, clothing, shoes and hats, luggage, home textiles, automotive interiors, decoration, packaging, abrasives, advertising, medical supplies, sanitary products, building materials, toys, industrial fabrics, environmentally friendly filter materials etc.

How to choose the most suitable laminating machine?

A. What’s the detail material solution requirement?

B. What ‘s the material’s characteristics before laminating?

C. What’s the usage of your laminated products?

D. What’s the material properties do you need to achieve after lamination?

How can I install and operate the machine?

We offer detailed English instruction and operation videos. Engineer can also go abroad to your factory to install the machine and traning your staff to operation.

Shall I see the machine working before order?

Welcome friends around the world to visit our factory for any time.

Product detail pictures:

Related Product Guide:

Our company aims to operating faithfully, serving to all of our customers , and working in new technology and new machine constantly for OEM/ODM China Plastic/Pe Foam Sheet Laminating Machine - Kraft paper tape coating machine – Xinlilong , The product will supply to all over the world, such as: belarus, UAE, Indonesia, We pay high attention to customer service, and cherish every customer. We have maintained a strong reputation in the industry for many years. We are honest and work on building a long-term relationship with our customers.

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.