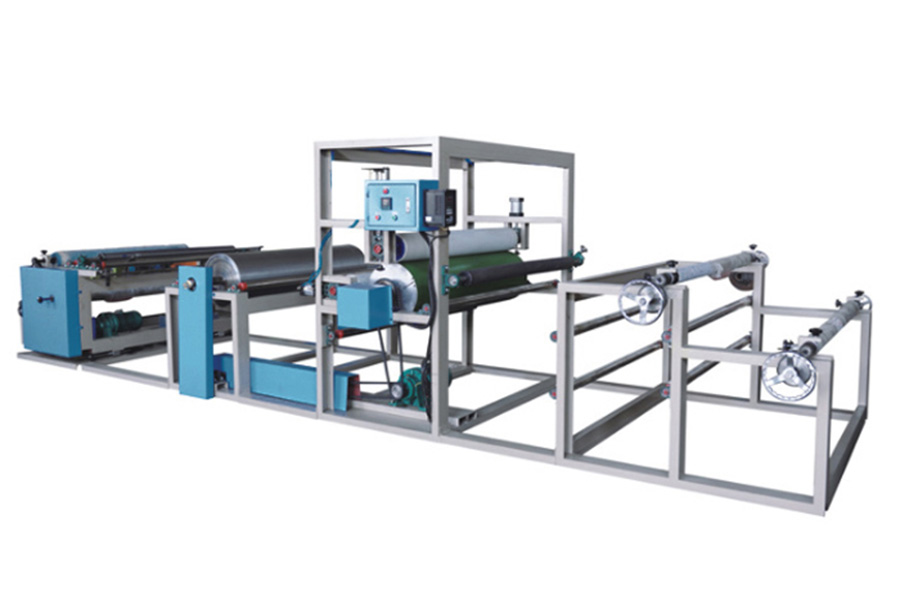

OEM Manufacturer Oily Glue Laminating Machine - Fabric to film laminating machine – Xinlilong

OEM Manufacturer Oily Glue Laminating Machine - Fabric to film laminating machine – Xinlilong Detail:

The feeding device and edge position control mechanism use simple and fast design and have the features of power-saving, space-saving and nimble operation.

We can design and manufacturer laminating machines according to customer’s different requirements, even for a vary of cloth materials or thin films, the processes for different sizes, different operation temperatures and different tension limit are all could be completed with the best solutions.

Xinlilong has professional experience of more than 20 years for manufacturing laminating machines, could satisfy a vary of laminating requirements to cloth fabrics and thin films etc.

Structure

Fabric to Film Laminating Machine

1. Applied for gluing and laminating of fabric, nonwoven, textile, waterproof, breathable films and etc.

2. Aided by PLC program control and man-machine touch interface, easy to operate.

3. Advanced edge alignment and scothing devices, this machine increases the degree of automation, saves labor costs, relieves labor intensity, and enhances production efficiency.

4. With PU glue or solvent based glue, the laminated products have good adhesive property and touch well. They are washable and dry-cleanable. Due to the glue is in the point form when laminating, the laminated products are breathable.

5. Efficient cooling device enhances the lamination effect.

6. Sewing cutter is used to cut the raw edges of the laminated materials.

Laminating Materials

1.Fabric + fabric:textiles, jersey, fleece, Nylon, Velvet, Terry cloth, Suede,etc.

2.Fabric + films, such as PU film, TPU film, PE film, PVC film, PTFE film,etc.

3.Fabric+ Leather/Artificial Leather,etc.

4.Fabric + Nonwoven

5.Sponge/ Foam with Fabric/ Artificial Leather

Main Technical Parameters

|

Effective Fabrics Width |

1600~3200mm/Customized |

|

Roller Width |

1800~3400mm/Customized |

|

Production speed |

10-45 m/min |

|

Demension (L*W*H) |

11800mm*2900mm*3600mm |

|

Heating Method |

heat conducting oil and electric |

|

Voltage |

380V 50HZ 3Phase / customizable |

|

Weight |

about 9000kg |

|

Gross Power |

55KW |

Widely Used In

Product detail pictures:

Related Product Guide:

Our business promises all users of the first-class items and the most satisfying post-sale company. We warmly welcome our regular and new prospects to join us for OEM Manufacturer Oily Glue Laminating Machine - Fabric to film laminating machine – Xinlilong , The product will supply to all over the world, such as: Senegal, United Arab Emirates, Lebanon, Further, we are supported by highly experienced and knowledgeable professionals, who have immense expertise in their respective domain. These professionals work in close coordination with each other to offer our clients an effective range of products.

This supplier stick to the principle of "Quality first, Honesty as base", it is absolutely to be trust.