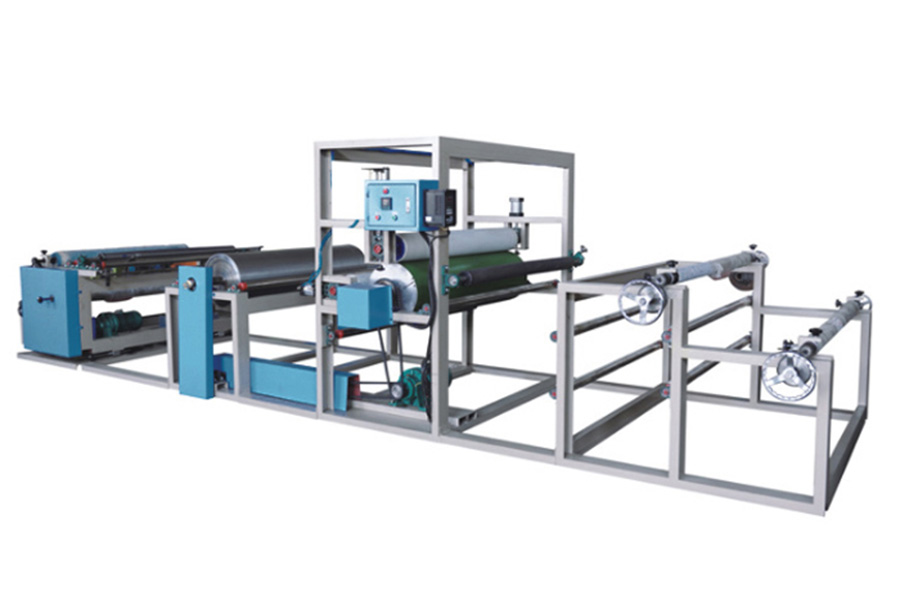

Laminate Table Cloth - Flame spraying bonding machine – Xinlilong

Laminate Table Cloth - Flame spraying bonding machine – Xinlilong Detail:

By flame lamination making the compound of two or three layers. There have three components (single, resp. sandwich-lamination) by using the adhesion characteristics of the foam which is melted by the line gas burner.

Flame laminating machine are used to join thermoplastic materials like foam made of polyester, polyether, polyethylene or various adhesive foils and textile, PVC-foils, artificial leather, non-wovens, papers or other materials.

Depending on the machine construction, single or sandwich laminations can be made. The materials are taken from bales or plates.

A line gas burner, which is installed across the whole working width, is melting the foam, resulting in an adhesive film. Inside the calender, the foam and the top fabric, resp. the backlining, are permanently joined together when running through the laminating gap.

Flame Lamination Machine Features

1. It adopts advanced PLC, touch screen and servo motor control, with good synchronization effect, no tension automatic feeding control, high continuous production efficiency, and the sponge table is used to be uniform, stable and not elongated.

2. The three-layer material can be combined in one time through the double-fired simultaneous combustion, which is suitable for mass production. Domestic or imported fire platoons can be selected according to the product requirements.

3. The composite product has the advantages of strong overall performance, good hand feeling, water washing resistance and dry cleaning.

4. Special requirements can be customized as needed.

Main Technical Parameters

|

Burner Width |

2.1m or customised |

|

Burning Fuel |

Liquefied natural gas (LNG) |

|

Laminating speed |

0~45m/min |

|

Cooling method |

water cooling or air cooling |

Widely Used In

Automotive industry (interiors and seats)

Furniture industry (chairs, sofas)

Footwear industry

Garment industry

Hats, gloves,bags, toys and etc

Characteristics

1. Gas Type: Natural Gas or Liquefied Gas.

2. The water cooling system well enhances the lamination effect.

3. The air exhaust diaphragm will exhaust the odor.

4. Fabric spreading device is installed to make the laminated material smooth and neat.

5. The strength of the bonding depends on the material and the foam or EVA selected and the processing conditions.

6. With high integrity and long term adhesive durability, the laminated materials touch well and is dry washable.

7. Edge tracker, tensionless fabric unwinding device, stamping device and other auxiliary equipment can be optionally installed.

Product detail pictures:

Related Product Guide:

We have probably the most state-of-the-art output equipment, experienced and qualified engineers and workers, recognized good quality manage systems plus a friendly skilled income workforce pre/after-sales support for Laminate Table Cloth - Flame spraying bonding machine – Xinlilong , The product will supply to all over the world, such as: Florence, Bolivia, Albania, With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in public placesand other industries. Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.