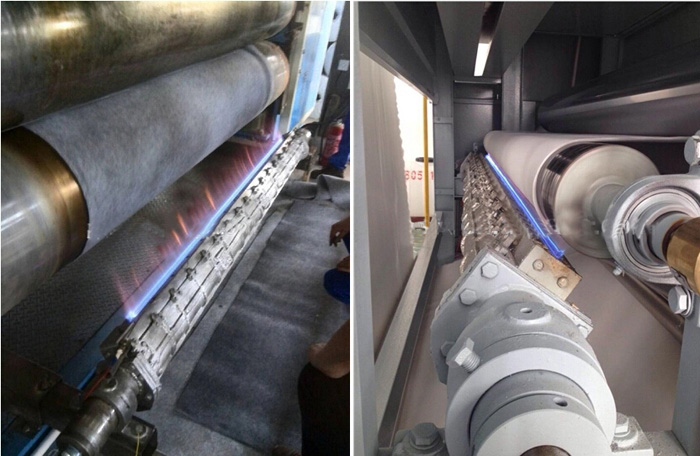

Nplaim spraying bonding tshuab

Los ntawm hluav taws xob lamination uatuskev sib xyaw ntawm oblos yog peb txheej. muaj three Cheebtsam (ib zaug, resp. sandwich-lamination) los ntawm kev siv cov yam ntxwv adhesion ntawm cov npuas dej uas yog yaj los ntawm cov kab roj burner.

Nplaim laminating tshuab yog siv los koom nrog cov ntaub ntawv thermoplastic xws li ua npuas ncauj ua los ntawm polyester, polyether, polyethylene los yog ntau yam nplaum nplaum thiab textile, PVC-foils, tawv tawv, tsis-wovens, ntawv lossis lwm yam ntaub ntawv.

Nyob ntawm kev siv tshuab, ib leeg lossis sandwich laminations tuaj yeem ua.Cov ntaub ntawv yog muab los ntawm bales los yog phaj.

Cov kab hluav taws xob hluav taws xob, uas tau teeb tsa thoob plaws tag nrho kev ua haujlwm dav, yog melting ua npuas ncauj, uas ua rau cov nplaum nplaum.Nyob rau hauv lub calender, ua npuas ncauj thiab sab saum toj ntaub, resp.lub backlining, yog mus tas li koom ua ke thaum khiav los ntawm qhov sib txawv laminating.

Nplaim Lamination Tshuab Nta

1. Nws txais PLC siab heev, kov lub vijtsam thiab servo lub cev muaj zog tswj, nrog cov txiaj ntsig zoo synchronization, tsis muaj qhov nro tsis siv neeg pub noj, siab nruam ntau lawm efficiency, thiab daim txhuam cev lub rooj yog siv los ua ib yam, ruaj khov thiab tsis elongated.

2. Cov khoom siv peb txheej tuaj yeem sib xyaw ua ke hauv ib lub sijhawm los ntawm kev sib xyaw ua ke ob zaug, uas yog tsim rau kev tsim khoom loj.Cov hluav taws kub hauv tsev lossis txawv teb chaws tuaj yeem xaiv tau raws li cov khoom xav tau.

3. Cov khoom sib xyaw muaj qhov zoo ntawm kev ua tau zoo tag nrho, kev xav zoo ntawm tes, dej ntxuav tsis kam thiab ntxuav kom qhuav.

4. Cov kev cai tshwj xeeb tuaj yeem ua raws li qhov xav tau.

Main Technical Parameters

| Burner Dav | 2.1m lossis customized |

| Roj hlawv | Liquefied natural gas (LNG) |

| Laminating ceev | 0 ~ 45m / min |

| Txoj kev ua kom txias | dej txias los yog cua txias |

Siv dav hauv

Automotive kev lag luam (thaum sab hauv thiab rooj zaum)

Kev lag luam rooj tog (lub rooj zaum, sofas)

Kev lag luam khau

Kev lag luam tsoos tsho

kaus mom, hnab looj tes, hnab, khoom ua si thiab lwm yam

Yam ntxwv

1. Hom Gas: Cov Roj Ntsig lossis Liquefied Gas.

2. Cov dej txias txias zoo txhim kho cov nyhuv lamination.

3. Cov pa tawm diaphragm yuav tso cov ntxhiab tsw.

4. Npuag kis cov cuab yeej raug teeb tsa ua kom cov khoom laminated du thiab zoo.

5. Lub zog ntawm kev sib txuas yog nyob ntawm cov khoom siv thiab ua npuas ncauj lossis EVA xaiv thiab cov txheej txheem ua haujlwm.

6. Nrog rau kev ncaj ncees thiab lub sij hawm ntev ntawm cov nplaum nplaum, cov ntaub ntawv laminated kov zoo thiab yog qhuav washable.

7. Ntug tracker, tensionless npuag unwinding ntaus ntawv, stamping ntaus ntawv thiab lwm yam auxiliary cuab yeej yuav xaiv tau ntsia.